What Are the Flavor Notes of Costa Rica CriCita Estate's Pressure Honey Process?

Professional coffee knowledge exchange and more coffee bean information, please follow Coffee Workshop (WeChat official account: cafe_style).

What are the flavors of Costa Rica's Creatika Estate pressure honey processing? Does pressure honey processing belong to aerobic or anaerobic fermentation?

Region: Western Valley

Varieties: Caturra, Catuai

Altitude: 1750 meters

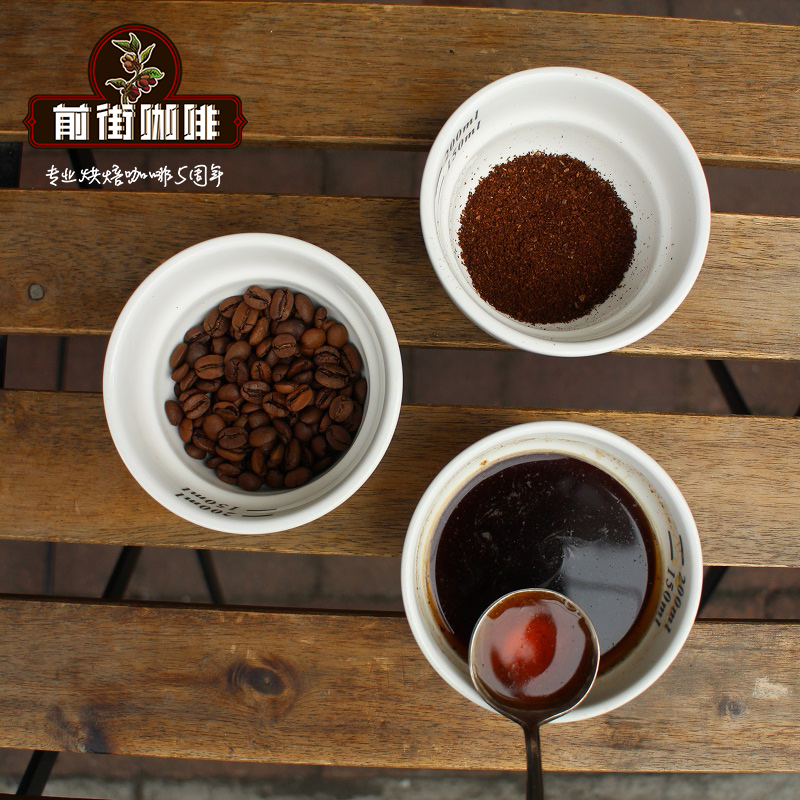

Flavor: Green apple, raisin, walnut, brown sugar, raw chocolate, root beer candy

What is "Pressure Honey Processing"?

100% ripe fruits are manually harvested and taken to the processing plant to remove pulp and perform "anaerobic fermentation." The average fermentation time is 24 hours, after which they are sent to a greenhouse for 4 days to remove the mucilage layer, then placed on African beds for 18-20 days for final drying. Finally, the coffee is sealed in barrels.

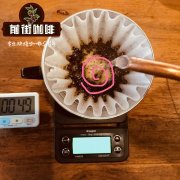

FrontStreet Coffee's recommended brewing method: Pour-over

Grind size: 3.5 (Japan's small Fuji R440)

V60 filter cup, 15g coffee grounds, water temperature 90°C, grind size 3.5, coffee-to-water ratio 1:15

30g water for bloom, bloom time 30s

Segmented brewing: Pour water to 120g, pause, then slowly pour to 225g

That is, 30-120-225g

The Four Key Elements of This Processing Method-

1. Shade System

The shade system effectively blocks sunlight, allowing the pulp to generate more sugars, resulting in coffee with more sweetness and wonderful, bright acidity.

2. Stainless Steel Containers

Coffee beans are placed in stainless steel containers for fermentation immediately after picking, abandoning traditional cement or terracotta containers. These traditional containers absorb coffee flavors rather than retaining more coffee flavor in the pulp. Using stainless steel containers results in cleaner coffee flavors.

3. Carbon Dioxide

The containers holding the coffee beans are then sealed and pressurized with carbon dioxide, ensuring no oxygen remains inside. This approach guarantees that all coffee flavors and aromas are retained in the coffee, making the coffee's flavor more pronounced.

4. Controlled Temperature

Finally, these containers holding coffee beans are placed in a controlled environment, mastering more variables to replicate consistent coffee bean flavors. Traditional processing methods are affected by weather, humidity, and other factors, making it difficult to ensure consistent flavor in each batch.

Pressure honey processing is the currently popular anaerobic processing method. Mostly called anaerobic fermentation or pressure honey processing. If translated directly from the producing region, it's pressure honey processing. It's similar to winemaking - putting the removed coffee pulp together with mucilage-covered coffee beans into barrels for fermentation. The high pressure inside the barrels slows down fermentation, so those cinnamon biscuit flavors are also products of anaerobic fermentation.

What steps does honey processing include?

The honey processing method can...

First, coffee farmers must select ripe coffee cherries from coffee trees, then peel off the outer skin while retaining the mucilage layer. The mucilage layer retains a high proportion of sugars and acidity, and these sweet and acidic elements are key to honey processing. The most complex and demanding part of honey processing is: drying.

Timing must be well-controlled, and duration is crucial. If the drying time is too short, substances from the mucilage layer cannot transfer to the coffee beans. However, the time cannot be too long either - action must be quick to avoid over-fermentation inside the beans, which would result in moldy beans.

So how to achieve balance?

For the first few days when beans are placed on sun-drying racks or cement surfaces, they must be turned several times every hour until the desired moisture content is reached. This step usually takes 6-10 hours. For the next 6-8 days, they need to be turned at least once daily. Time-consuming, isn't it? The reason honey processing sun-drying is so time-consuming is that beans absorb moisture from the air every night, requiring more time for drying the next day.

When coffee drying is complete, it can undergo drying treatment and roasting, just like other processing methods.

Why is honey processing so popular among coffee farmers?

Honey processing initially gained attention when people saw that this processing method could consistently improve their coffee bean quality. It originated in Costa Rica and is currently trending.

Why did Costa Rican coffee farmers initially consider using honey processing?

When coffee farmers want to improve their coffee quality or selling price, they have three choices: change the coffee tree variety, change the growing altitude, or change the processing method. Just like most people brewing coffee who want to use simpler methods like adjusting grind size and coffee amount first, then adjusting coffee machine water volume, pressure, and temperature; most coffee farmers also want to change the processing method first, before considering growing new tree varieties or moving their estate - approaches that require investing more time and substantial money.

Why is honey processing so wonderful?

Since honey processing is so difficult to do well and time-consuming, you might wonder if it's really worth all the effort.

Without a doubt, it's absolutely worth it.

Honey-processed coffee generally has wonderful sweetness and balanced fruit acidity. The flavor isn't as intense as natural-processed coffee, but it's fresher and more aromatic. Why not?

The key to these flavor differences comes from the sugars and acidity in the mucilage layer. During the drying period, the sugars in the mucilage layer become increasingly concentrated, and these sugars penetrate into the coffee beans.

The subsequent steps are not simple - they are both time-consuming and require attention to processing details.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Hand Pour Hachira Coffee Beans Tutorial_Hachira Coffee Price Per Cup_Hachira Name Origin Story

Professional coffee knowledge exchange For more coffee bean information please follow Coffee Workshop (WeChat official account cafe_style) 90+ Hachira Coffee Ninety plus Hachira N2 Hand Pour and Aiyarepression Name: 90+NinetyPlus Hachira Variety: Ancient Heirloom varieties Processing Method: Natural Process Region/Estate: Wellega/Sidama Yirgacheffe

- Next

90+ Premium Coffee Bean Hachira Price Per Pack | How to Brew Hachira Coffee Beans for Best Taste

Professional coffee knowledge exchange For more coffee bean information Please follow Coffee Workshop (WeChat official account cafe_style) 90+ Premium Coffee Hachira Coffee Hachira HACHIRA coffee comes from Aricha developed jointly with S.A Bagersh from 2006-2008, featuring excellent fruity notes and floral aromas, along with quite concentrated elderberry and blackberry fruit, sometimes also carrying

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee