Ethiopian Washed Yirgacheffe Brewing Guide and Flavor Characteristics Introduction

Which coffee growing region did you first discover the washed processing method from? I bet many of you are thinking of Yirgacheffe right now~ After the Ethiopian government introduced the washed processing method from Central and South America in the 1970s to improve coffee bean quality, the town of Yirgacheffe, which was then part of the Sidamo region,凭借 the washed processing method to present bright acidity, white floral notes, and tea-like sensations, instantly capturing the hearts of many coffee connoisseurs! FrontStreet Coffee believes that the washed processing method best represents the fundamental character of a coffee bean, while also being the best method to reflect the quality of the coffee beans.

What is the Washed Processing Method?

All processing methods离不开阳光暴晒干燥。Coffee fruits contain large amounts of sugar, and if exposed to high temperatures for long periods, the sugar inside can easily ferment, causing the coffee beans to develop pungent fermented acidity. At the same time, natural processing depends on favorable weather. During humid seasons or continuous rainy periods, if coffee fruits don't dry in time or dry unevenly, they will start to rot, causing the coffee beans to develop rotten flavors.

To solve this problem, people began experimenting with using water sources to first remove the fruit skin, pulp, and mucilage, reducing the moisture content of coffee fruits before drying. This significantly shortens the sun-drying time, and thus the washed processing method was born. Before honey processing became popular in Costa Rica, washed processing was the dominant method. In 1821, Costa Rica vigorously developed its coffee cultivation industry, and by 1830, they had begun using washed processing. By 1905, over one hundred years ago, Costa Rica already had more than 200 washed processing mills.

Washed Processing Method Process/Steps

① Cleaning/Collection/Floatation/Selection

Coffee fruits are transported to the processing mill within 6-12 hours after harvesting for weighing, then soaked and cleaned. The purpose is to pick out the "little bad guys" that float on the surface due to insufficient density and clean away branches, sand, and stones.

② Removing Fruit Skin and Pulp

Machines are used to remove the fruit skin and pulp, leaving only coffee beans wrapped in parchment. At this point, there's still a layer of mucilage outside the beans, so fermentation is needed to produce acidity that makes the mucilage fall off.

③ Fermentation & Mucilage Removal

This layer of mucilage is the pectin part. The pectin mucilage has strong adhesion and is not easy to remove, so it needs to be placed in clean water tanks for about 18-36 hours, allowing the pectin to ferment and produce acid to decompose the mucilage.

④ Cleaning Mucilage

After the mucilage decomposes, a small amount of clean water is injected and stirred to make the coffee beans' mucilage decomposition products fall off. After cleaning, you'll get coffee beans wrapped in parchment and husk.

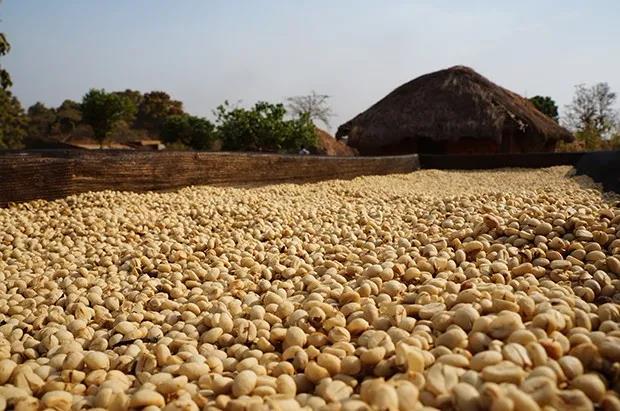

⑤ Sun Drying

After cleaning, defective coffee beans are selected out, then spread on cement floors/waterproof tarps/drying beds for sun drying. The drying duration depends on weather conditions, generally ranging from 5-14 days. After drying, the moisture content of coffee beans drops from 55% to 11%.

⑥ Storage

After drying is complete, coffee beans are stored with their parchment on. The parchment is only removed before the coffee beans are exported.

Flavor and Taste Characteristics of Washed Processing

Since the "little bad guys" are roughly picked out in all processing steps, and defective beans are picked again before sun drying, plus the fermentation process in water tanks gives coffee beans brighter acidity. Therefore, FrontStreet Coffee believes that the biggest flavor characteristic of washed processing is bright fruit acidity, with the overall coffee being clean and fresh, with rich layers.

How Can FrontStreet Coffee's Washed Yirgacheffe Be Brewed to Taste Better?

FrontStreet Coffee recommends a medium-fine grind size (78% pass rate through Chinese standard #20 sieve). Too coarse and you can't extract the body substances, making the brewed coffee seem thin. Too fine and it's easy to over-extract at high water temperatures, making the brewed coffee prone to bitterness. Water temperature can be 90-91°C, which allows the bright fruit acidity to be more fully expressed. Due to the higher acidity, a brewing ratio of 1:16 can be used to dilute the acidity concentration, allowing other light flavors to emerge (such as floral and tea-like notes). FrontStreet Coffee suggests using a segmented pouring technique, where different flavor compounds can better express themselves during the gradual temperature increase of the coffee bed.

Brewing method: First pour 30g of water for a 30-second bloom, at which point the coffee expands quite fully. For the second stage, pour 120g of water in small circles from the center. Pour height is 5cm, with gentle force, no need to stir deliberately. Wait until the water level drops to 1/2 of the coffee bed before starting the third pour. In this stage, pour gently from center outward in circles, with water flow at approximately 4g/s, until reaching 240g to end the pour. End the extraction when all coffee liquid has dripped through the filter, with a total time of 2'00"-2'10".

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Introduction to Costa Rican Coffee Estates - Diamond Mountain Coffee Estate Costa Rican Coffee Flavor Profile

Coffee cultivation in Costa Rica began in 1779 with coffee introduced from Cuba, with the first coffee exports occurring in 1820. Today, there are approximately 32,000 coffee farmers, with each farmer cultivating an average area of less than one hectare (10,000㎡). Costa Rica has a population of 4.1 million (as of 2006).

- Next

Arabica Bean Processing Method Green Bean Processing Semi-washed Processing Method Peru Washed Processing

The semi-washed method first removes the outer skin with water, then proceeds to sun-drying. This is a relatively new and quite rare method. This method is only suitable for specific regions in certain countries and requires a considerably long drying period. The coffee produced through this processing method is quite sticky, and the mucilage does not get removed through fermentation in the tanks. Therefore, this

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee