How Does the Wet Hulling Method That Creates Mandheling Flavor Work? Why is Wet Hulling Called Semi-Washed Processing?

Whenever Indonesia is mentioned, people invariably refer to the region's most famous coffee - "Mandheling." Mandheling's unparalleled regional flavor and distinctive smooth taste characteristics directly distinguish it from other deep-roasted beans from regions like Brazil and Colombia, leaving people of the last century with a delicious impression.

Of course, behind this deliciousness, in addition to the effect of Robusta genes, there's also the unique processing method from Indonesia - the Wet Hulling method! This is the post-processing method that FrontStreet Coffee wants to share in this article.

What is Wet Hulling?

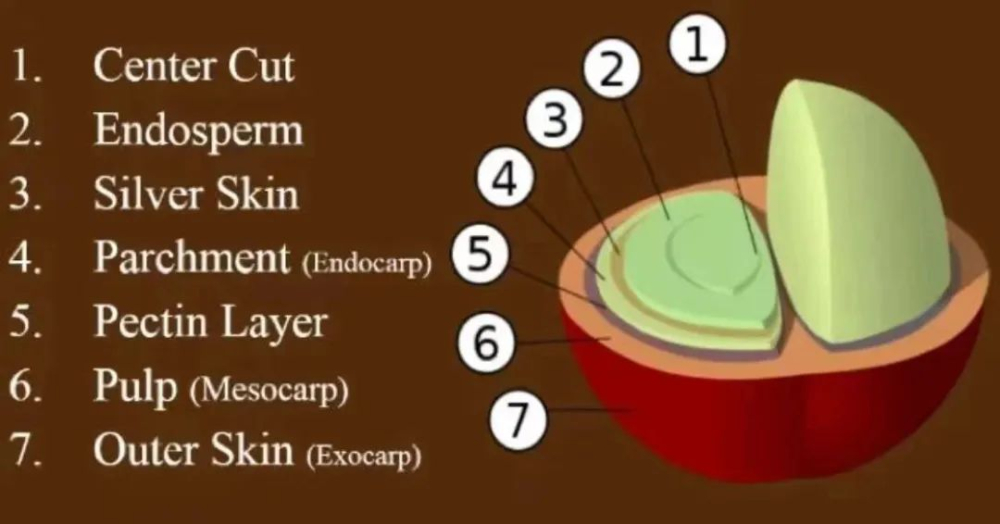

In the post-processing of coffee raw beans, most processing methods are developed according to local conditions - a drying method for coffee raw beans created based on the local environment, and Wet Hulling is no exception! Wet Hulling is difficult to understand literally, so FrontStreet Coffee won't keep you in suspense here~ Wet Hulling means that when the coffee raw beans have not yet reached a dry state, a certain substance is hulled out, and that substance is the parchment (endocarp).

In conventional processing methods, the parchment layer is usually removed at the end of the process, while Wet Hulling removes it during the process - when the beans are halfway through processing! Therefore, Wet Hulling is also known as Wet Hulling.

Why Does Indonesia Use Wet Hulling?

As FrontStreet Coffee mentioned above, it's adapting to local conditions. Indonesia's local climate is humid, with short daily sunshine hours and humidity consistently between 70%-90% throughout the year. Therefore, it cannot directly dry coffee fruits in one go through long-term sun exposure like other coffee-producing regions. Short periods of sunshine can easily cause coffee fruits to grow mold - that is, to become moldy! At the same time, due to unpredictable climate changes, it also cannot use the washed processing method. Because it's difficult to let coffee beans ferment in water and then get sufficient sunlight to dry them. So, Wet Hulling was born!

Wet Hulling is often jokingly referred to as "semi-washed processing" because its processing method is closer to washed processing but not entirely washed. What does that mean? Wet Hulling initially adopts the front part of washed processing, fermenting the coffee raw beans. Then the parchment-covered coffee beans are sun-dried. After drying to a certain extent, the parchment layer is removed, and then dried again. This approach allows coffee beans to complete drying in the shortest time possible, reducing mold growth. Next, follow FrontStreet Coffee to see the Wet Hulling process~

The Wet Hulling Process

The front part of Wet Hulling is all washed processing, so after picking fresh fruits, clean water is first used for flotation selection. Bad fruits of poor quality that float on the water surface are picked out; then, machines are used to remove the outer skin and pulp of the coffee fruits, taking out the coffee raw beans with pectin and parchment layers; after taking out the coffee raw beans, they are placed in water pools for fermentation to decompose the pectin layer attached to the beans, with the end time determined by conditions, generally within the range of 12-36 hours; when the water fermentation ends, the washing process is complete, and we enter the latter part of Wet Hulling. Farmers will place the fermented parchment-covered coffee raw beans under the sun for drying. If the weather is consistently sunny with ample sunshine, the moisture content of the coffee beans can quickly drop to the 30%-50% range; then drying is stopped, and a hulling machine is used to remove the parchment layer of the coffee beans; finally, drying continues until the moisture content of the coffee beans drops to 12%!

The Product of Wet Hulling - Elephant Beans

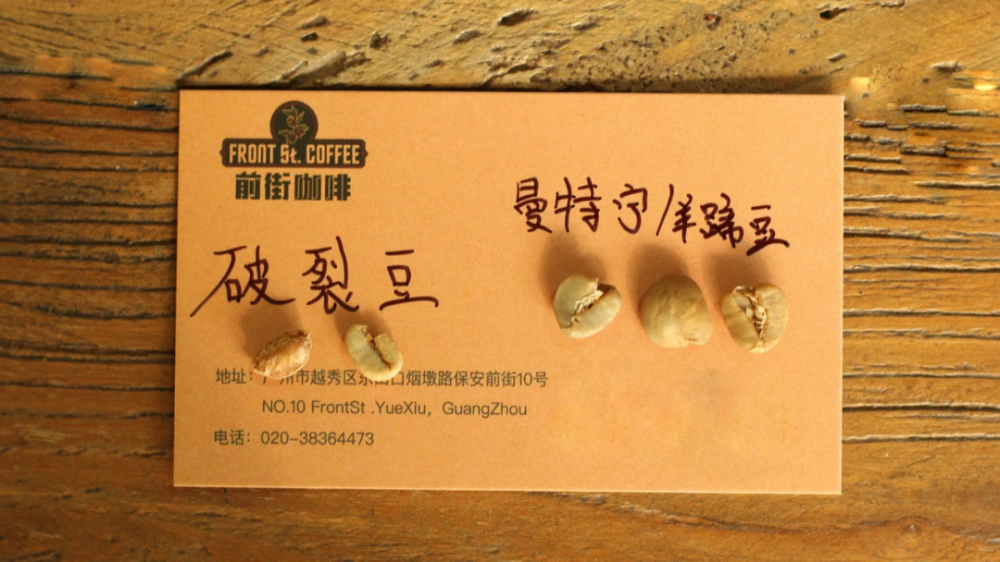

Because the hulling machine that removes the parchment layer is quite rough, it tends to crush and squeeze the coffee raw beans while removing the parchment layer. Especially at both ends of the beans. Friends who have seen Mandheling raw beans know that some beans have crack marks resembling hooves, so they are called "Elephant Beans" (or sometimes "goat hoof beans").

(The beans on the right are Elephant Beans) Then there are rumors claiming that it is precisely the appearance of Elephant Beans that creates the characteristic flavor of Mandheling. But that's not actually true! Elephant Beans are simply damaged beans and don't have much impact on flavor. So, dear friends, don't be misled~

- END -

FrontStreet Coffee

No. 10, Bao'an Qianjie, Yandun Road, Dongshankou, Yuexiu District, Guangzhou, Guangdong Province

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Should You Pre-wet Filter Paper Before Brewing Coffee? What Are the Benefits of Wet Filter Paper and How Does It Affect Extraction?

Pre-wetting filter paper before brewing has become a habit for most coffee enthusiasts and is widely considered an important detail. But is it really that crucial? Why do many brewing masters and champions not perform this step in their tutorial videos? This has inevitably left many coffee lovers wondering

- Next

Does Cold Brew Coffee with Milk Taste Good? An Introduction to the Correct Ratio and Brewing Method

Open your phone's weather app and see a screen full of 30-degree high temperatures - summer and heat are truly upon us! It's time to get all kinds of iced coffee ready! When it comes to the most popular homemade iced coffee varieties, cold brew is definitely on the list. Just prepare a pot before bed, put it in the refrigerator, and filter it when you wake up

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee