Introduction to Gakuyuini Processing Station in Kenya and Coffee Bean Processing: Thirikwa Farmers Cooperative

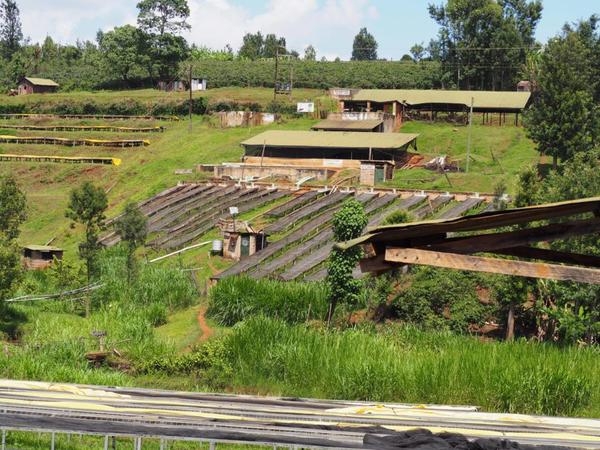

Kenya Gakuyuini Processing Station

Kenya's coffee industry is renowned for its cooperative system that integrates production, processing, and marketing. Approximately 70% of Kenyan coffee is produced by small-scale growers. Today, we'd like to focus specifically on the Gakuyuini Processing Station.

Coffee Details

Coffee Grade: AB Fully Washed

Farm/Cooperative/Station: Gakuyuini Processing Station

Variety: SL28, SL34

Processing: Fully Washed

Altitude: Farmers - 1,500 to 1,900 meters above sea level; Washing Station - 1,600 to 1,700 meters above sea level

Owner: Member farmers deliver cherries to Gakuyuini Coffee Processing Station

Sub-region/Town: Kerugoya and Kianyaga, Kirinyaga

Region: Central Kenya

Farm Size: Average 250 trees

Bag Size: 30kg

Harvest Months: Central Kenya: May to July (early crop) | October to December (late crop)

Today, more than 600,000 smallholders with less than 5 acres of cultivation area account for 99% of Kenya's coffee cultivation population. Their farms cover over 75% of the total coffee cultivation area and produce nearly 70% of the country's coffee. These farmers are organized into hundreds of Farmers' Cooperative Societies (FCS), all of which operate at least one factory. The remainder of the annual production is grown and processed by small, medium, and large estates. Most larger estates have their own washing stations.

Among the more than 1,500 active members who contribute cherries to the Gakuyuini Washing Station, over a quarter (more than 670) are women. Together, they harvest approximately 250 tons of cherries annually and deliver them to the station.

The station is owned and managed by the Thirikwa Farmers Cooperative Society. The cooperative is led by 5 democratically elected board members. Farmers who deliver cherries to Gakuyuini typically own less than 1 hectare of land each. On this small piece of land, they grow both subsistence and cash crops throughout the year to support their families. Each farmer has an average of about 250 coffee trees, and their trees are often intercropped with other crops. While low yields might mean reduced profits, many farmers see specialty coffee cultivation as a way to increase the value of each cherry picked. Farm labor is typically provided entirely by family members, which often makes it easier to maintain professional cultivation and picking practices. Many farmers also grow tea, corn, and beans for local consumption or to sell for additional cash income.

Harvest and Post-Harvest

Farmers hand-pick ripe cherries and deliver them to the Gakuyuini factory on the same day for processing. At the factory, cherry sorting takes place before pulping, where ripe cherries are separated from unripe, overripe, and foreign matter.

The factory uses clean river water for processing and recirculates it before discharging it into seepage pits. The coffee is then dried on raised beds before being sent to the dry mill for secondary processing.

Farmers selectively hand-pick ripe cherries and deliver them to the Gakuyuini Washing Station. The cherries are sorted at the entrance, where unripe and overripe ones, as well as any foreign matter, are removed.

The sorted cherries are then added to a hopper and pulped. The cherry pulp ferments for 12 to 16 hours, then washed with clean water to remove any remaining mucilage. While the parchment is drying on raised beds, the wet parchment is sorted and any remaining damaged beans are removed. It is turned regularly to ensure even drying and covered during the hottest parts of the day and at night to prevent cracking and/or condensation. Drying time typically takes around two weeks, depending on the weather conditions at the time.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

The Historical Development Story of Bourbon Coffee Beans - Nicaragua Finca Divina Red Bourbon Coffee Bean Flavor

Bourbon is one of the world's most culturally and genetically significant varieties, renowned for its exceptional cupping quality at the highest altitudes. Bourbon coffee plants grow relatively tall with green leaf tips and produce uniformly sized beans, demonstrating excellent potential for high-altitude quality. However, they are susceptible to coffee leaf rust and nematode diseases while yielding extremely low production. French missionaries introduced these plants in the early 1700s.

- Next

Five Major Coffee Bean Certifications: What Are UTZ, Fair Trade, and Bird Friendly Certifications? Clifton Manor Rainforest Certification

Coffee certifications are everywhere—in grocery stores, restaurants, and even offices! Today's consumers have the right to know whether the coffee beans they purchase are certified. Certifications provide consumers with various third-party guarantees. They can demonstrate environmentally friendly agricultural practices and can even achieve organic certification. They can guarantee that no child labor was involved in the coffee production process. Some programs focus more on...

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee