What are the Differences Between Washed and Natural Coffee Beans? How to Taste the Differences After Grinding?

For more professional coffee knowledge and information, please follow Coffee Workshop (WeChat public account: cafe_style).

Coffee lovers who enjoy single-origin coffee have likely heard of washed and natural processing methods. After coffee cherries are harvested, they undergo a series of steps to extract the coffee beans from inside - this entire process is known as coffee processing. Even coffee cherries from the same region, same plot, and same batch will produce beans with different flavor characteristics when processed using different methods. FrontStreet Coffee believes that washed processed coffee beans exhibit brighter acidity with an overall fresh and clean flavor profile, while naturally processed coffee beans have fermented notes with a smooth, juice-like mouthfeel. Next, FrontStreet Coffee will explain the differences between washed and natural processing methods.

Washed Processing Method

As the name suggests, the washed processing method requires large amounts of fresh water to treat coffee cherries. Some coffee growing regions cannot use this method due to geographical lack of water sources, while poorer regions avoid it because the extensive water use generates additional costs. Therefore, the washed processing method is commonly used in areas with abundant water sources or insufficient sunlight. FrontStreet Coffee believes that washed processed coffee has more prominent acidity, better clarity, medium body, and the most consistent green bean quality. African coffee regions often use the washed processing method, as it allows African coffee beans to better showcase their citrus-like bright acidity.

Washed Processing Steps:

Cleaning & Collection/Flotation/Rinsing

After harvesting, coffee cherries are immediately sent for processing, typically within 6 to 12 hours of picking. The cherries are first weighed, sorted, and then placed in water tanks for soaking, with the purpose of removing fruits that float due to insufficient quality.

Depulping

Next, the coffee cherries are sent to a depulper to remove the skin and pulp. This step is designed to remove the outer skin and pulp of the coffee cherry.

Fermentation/Demucilaging

The depulped coffee beans are transferred to fermentation tanks or barrels for static fermentation for 18 to 36 hours, with fermentation time determined by the ambient temperature. During fermentation, yeast produces enzymes, and lactic acid bacteria break down the sugars in the coffee mucilage. Lipids, proteins, and acids in the sugars degrade and convert into alcohol acidic acids. The coffee's aroma, color, and pH change, and the composition of the coffee mucilage is altered.

Washing

After fermentation and demucilaging, appropriate amounts of water are added to the tank to wash the coffee beans. During the washing process, stirring removes the decomposed mucilage from the bean surface, leaving only the coffee parchment, silver skin, and green beans.

Drying

The washed coffee beans are sorted to remove defective beans. They are then sent to drying areas (tarps, cement patios, raised beds, etc.) for drying. The drying time depends on environmental and climatic factors, typically ranging from 5 to 14 days. During this time, the moisture content of the coffee beans decreases from 55% to 11%.

Storage

After drying is complete, the coffee beans are called parchment coffee - green beans still enclosed in their parchment layer. The parchment beans are sent to warehouses for storage and will undergo hulling before export.

As mentioned above, most African growing regions primarily use washed processing methods, but African washed processing differs from traditional methods. Africa uses the Kenyan K72-hour washed processing method.

Kenya employs a cyclic processing method of post-fermentation washing. After daily harvest, the highest quality coffee cherries are selected for depulping and fermentation, with a fermentation time of 24 hours, after which they are washed with clean river water. This is followed by another 24-hour fermentation in clean river water, then another wash, repeating this cycle three times to reach 72 hours, hence the name Kenyan 72-Hour Fermented Washed Processing Method, abbreviated as [K72].

K72-Hour Washed Processing Steps:

① First Wash and Fermentation

After coffee cherry harvest, water flow density sorting is performed, utilizing the density and quality differences of coffee beans for screening; high-density (heavier) coffee beans sink in water, while low-density beans float. Fully ripe, high-quality coffee cherries have high density and are selected for further processing. FrontStreet Coffee believes that Kenyan 72-hour fermented washed processed coffee beans, when fermented at low temperatures for extended periods and finally dried through sun dehydration, result in beans with brighter, cleaner, yet fuller flavors.

After selecting high-quality, sufficiently ripe fruits, the skin is removed and the beans undergo washed soaking, allowing the mucilage attached to the outer layer of the green beans to ferment. The mucilage contains natural sugars and alcohols, which play a crucial role in developing the coffee's sweetness, acidity, and overall flavor. The fermentation lasts up to 24 hours, removing 80-90% of the mucilage and leaving only the flavor within the coffee beans.

② Second Wash and Fermentation

Next, the coffee enters the second wash and fermentation cycle. After cleaning the coffee beans from the previous stage, they are soaked in water again for 24-48 hours. This process increases proteins and amino acids, creating complex and delicate layers of acidity in the coffee beans. Finally, all remaining mucilage is removed, and the coffee beans are moved to elevated racks for sun drying.

The fermentation lasts up to 24 hours, removing 80-90% of the mucilage, leaving only the flavor within the coffee beans. Finally, all remaining mucilage is removed, and the coffee beans are moved to elevated racks for sun drying. The drying time depends on weather conditions, typically requiring about 5-10 days to complete.

Natural Processing Method

Natural processing is one of the oldest and most traditional processing methods. Coffee cherries are dried immediately in the sun after harvesting. This method is more common in areas with abundant sunlight or scarce water resources, such as Ethiopia, where nearly 70% of coffee cherries undergo natural processing. FrontStreet Coffee believes that natural processing allows coffee cherries to dry naturally, enabling the beans to mature naturally within the fruit without interference from the external environment. Therefore, naturally processed coffee beans amplify their inherent flavors, with rich body, intense flavors, and emit sweet notes.

Natural Processing Steps:

1. Collection & Sorting

After harvesting, coffee cherries are first manually selected and sorted to remove defective coffee cherries, including overripe, underripe, insect-damaged ones, as well as foreign objects other than the fruit.

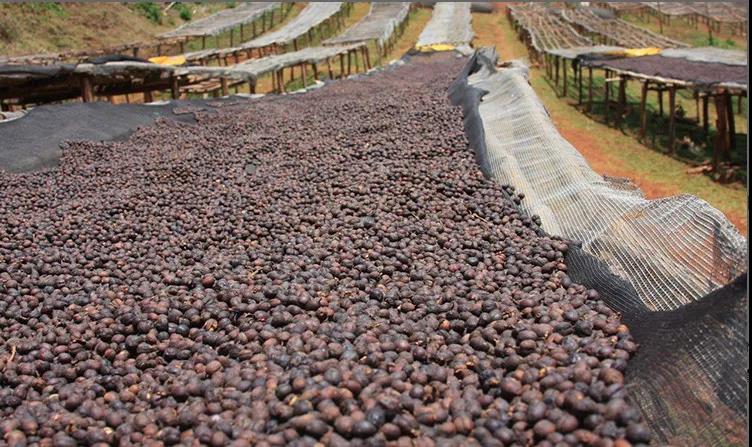

2. Drying

The sorted coffee cherries are sent to drying areas for drying. Different regions may use different drying racks - some use tarps, some use raised beds, and others use cement patios. The average drying time is 3 to 4 weeks, until the coffee moisture content drops to 11% to complete the drying process.

3. Depulping

After drying is complete, coffee cherries are sent to processing plants for depulping and hulling, and sometimes even polishing. The skin, pulp, and other parts are all removed during this step.

4. Sorting & Storage

The depulped green coffee beans undergo another round of sorting to remove beans with poor appearance. This reflects the quality of the coffee drying process - over-dried coffee beans are more fragile and may break into fragments during depulping; while under-dried coffee beans have excessive moisture content, with overly active water that can easily breed bacteria and cause mold growth.

Recently, FrontStreet Coffee launched a coffee that was originally only available in washed processing - starting from the 2020 harvest season, they introduced the naturally processed Panama La Esmeralda Geisha Blue Label. Next, FrontStreet Coffee will roast, cup, and brew both the washed and naturally processed Geisha Blue Label coffees from the same La Esmeralda farm to see what differences exist in the green beans, roasted beans, and flavor profiles.

Geisha Blue Label Green Bean Comparison

The green beans of Geisha Blue Label are long and pointed at both ends, with a distinctive elongated shape that makes them easy to recognize. When comparing naturally processed and washed processed green coffee beans, you'll clearly notice that naturally processed beans appear yellowish, while washed processed beans appear dark green with incomplete silver skin still attached.

FrontStreet Coffee's Geisha Blue Label Roasting Recommendations (Both processing methods use medium-light roasting with the same technique to highlight floral and fruity notes and Geisha's unique pleasant acidity):

Start at 180°C, heat at 130, damper open to 3; Return temperature at 1'32", when the drum temperature reaches 104°C, open damper to 4, heat unchanged; At 151.6°C drum temperature, the bean surface turns yellow, grassy aroma completely disappears, entering the dehydration stage. At 7'56", ugly wrinkles and black spots appear on the bean surface, toast aroma clearly transforms to coffee aroma, which can be defined as the prelude to first crack. At this point, listen carefully for the sound of first crack. At 8'30", first crack begins, open damper to 5. Develop for 1'28" after first crack, drop beans at 190°C.

Geisha Blue Label Roasted Bean Comparison

The biggest difference between naturally processed and washed roasted beans is that the silver skin of naturally processed beans comes off very cleanly, while washed processed beans retain yellowish silver skin along the center line. This is because during roasting, the silver skin along the center line is the most difficult to remove. In naturally processed beans, the outer silver skin is connected in one piece, making it easier to detach along with the center line silver skin, while the silver skin of washed beans attaches to the beans in fragments, and the silver skin in the center crack cannot easily separate.

FrontStreet Coffee Cupping Report

Washed Geisha Blue Label: Jasmine fragrance, citrus acidity, clean and bright, honey.

Natural Geisha Blue Label: Fermented wine aroma, fruity sweetness, melon, tropical fruits.

In summary, when the same coffee bean undergoes different processing methods, its flavor characteristics show clear trends. With natural processing, beans tend to have sweet and fermented notes, with richer fruit flavors and layered variations. Meanwhile, washed processed beans have cleaner, simpler flavors. With light roasting, the acidity and subtle aromas of the beans are further highlighted.

FrontStreet Coffee Brewing Recommendations

Dripper: V60 #01

Dose: 15g

Ratio: 1:15

Grind: BG6m (80% pass-through rate on #20 sieve)

Temperature: 90-91°C

*Regarding grind size, FrontStreet Coffee determines this through sieving. Based on grinding recommendations for pour-over coffee provided by the Specialty Coffee Association (SCA), FrontStreet Coffee combines this with practical brewing verification to use different grind sizes, which produces significantly different results. Additionally, each coffee bean variety requires a different grind size, which is the significance of sieving. If you don't have a sieve at home, FrontStreet Coffee recommends observing flow rate - if water flows too quickly, the grind is too coarse; if water flows too slowly, the grind is too fine.

FrontStreet Coffee uses segmented extraction, also called three-stage brewing: Use 30g of water for a 30-second bloom, then pour with a small circular motion to 125g for the first segment. When the water level drops and is about to expose the coffee bed, continue pouring to 225g and stop. When the water level drops and is about to expose the coffee bed again, remove the dripper. (Timing starts from the bloom) Extraction time: 1'52"-1'55".

Washed Geisha Blue Label Brewing Flavor: Smells of light jasmine flowers, with distinct citrus acidity that is very bright. The mouthfeel is clean and comfortable, with honey notes emerging in the middle to late finish.

Natural Geisha Blue Label Brewing Flavor: Smells of fermented aroma and fruity sweetness. Tasting reveals melon and tropical fruit sweetness, with a juice-like mouthfeel and overall very high sweetness.

For more specialty coffee beans, please add FrontStreet Coffee's private WeChat account: kaixinguoguo0925

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

How to Drink and Make Starbucks Flat White Coffee - Recommended Espresso Beans for Flat White Coffee

For professional coffee knowledge exchange and more coffee bean information, please follow Coffee Workshop (WeChat official account: cafe_style). Starbucks actually had another reason when they launched the Flat White in 2015. Coffee experts all know that Flat White is an imitation of Australia's national treasure coffee Flat White. Why would the coffee giant Starbucks...

- Next

Coffee Bean Wholesale | FrontStreet Coffee Single-Origin Coffee Bean List | Coffee Green/Roasted Bean Wholesale Price Report

Professional coffee knowledge exchange and more coffee bean information. Please follow Coffee Workshop (WeChat official account: cafe_style). FrontStreet Coffee Phone: 020-38364473 Website: www.makecoffee.cn Address: No. 10 Bao'an Frontsteet, Dadao Road, Yuexiu District, Guangzhou Premium Estate-Green Coffee Beans Country Bean Name Grade Region/Estate/Exporter Roast Level Processing Method Semi

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee