A Day in the Life of a Coffee Bean Roaster|What Does a Coffee Roaster Do?

Professional coffee knowledge exchange. For more coffee bean information, please follow Coffee Workshop (WeChat official account: cafe_style).

Yes, coffee bean roasters are indeed like boiler workers - buried in their work all day, firing and maintaining boilers. However, I prefer to call them Taoists - oblivious to worldly matters, focused solely on refining their craft.

Today, let's take a look at how our roasters serve everyone.

Normally, you'll see roasters silently staring at the roaster. Many people ask: What are they looking at?

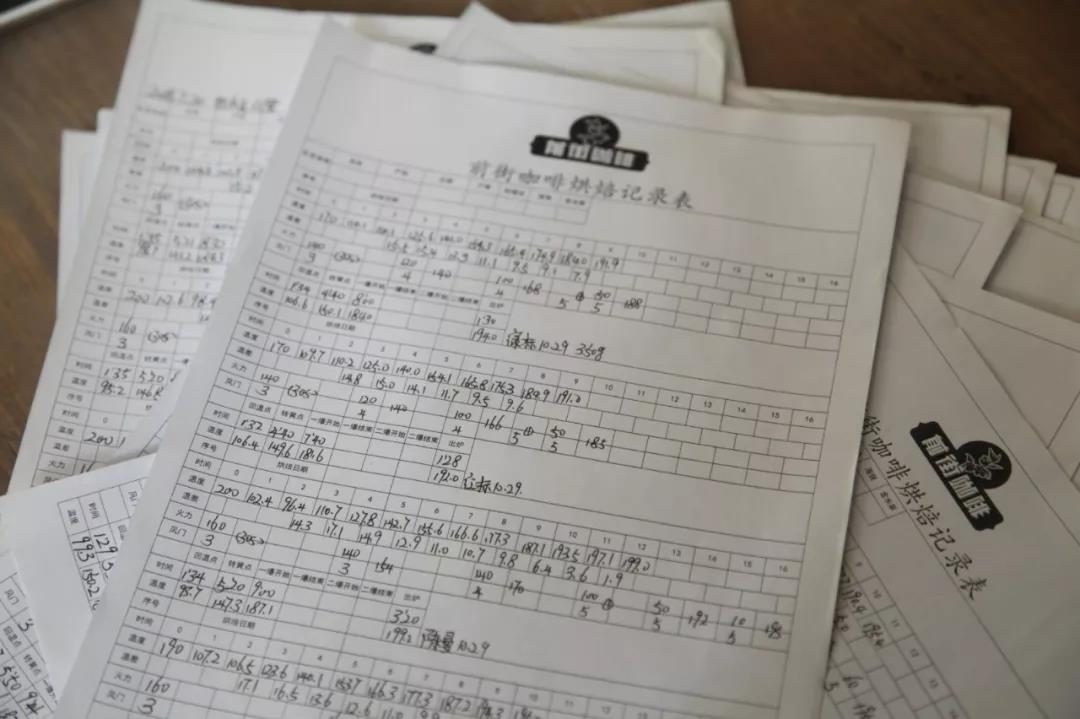

They maintain constant concentration - time, temperature, bean color, bean shape, smelling aromas, listening to sounds, recording roast curves, adjusting heat and airflow, determining when to drop the beans... For a ten-minute batch of coffee beans, roasters must engage all five senses throughout the entire process, all for the sake of delivering a good cup of coffee to the customer.

In addition to daily production, they must frequently fine-tune roast curves and conduct cupping to ensure quality. After all, coffee is an agricultural product that ultimately "depends on nature's bounty." Given the anticipated fluctuations in raw material quality, different batches of the same bean must be compared through roasting. Moreover, we haven't yet achieved direct purchase from origin, which introduces many variables in the intermediate stages. Therefore, regular adjustments are essential.

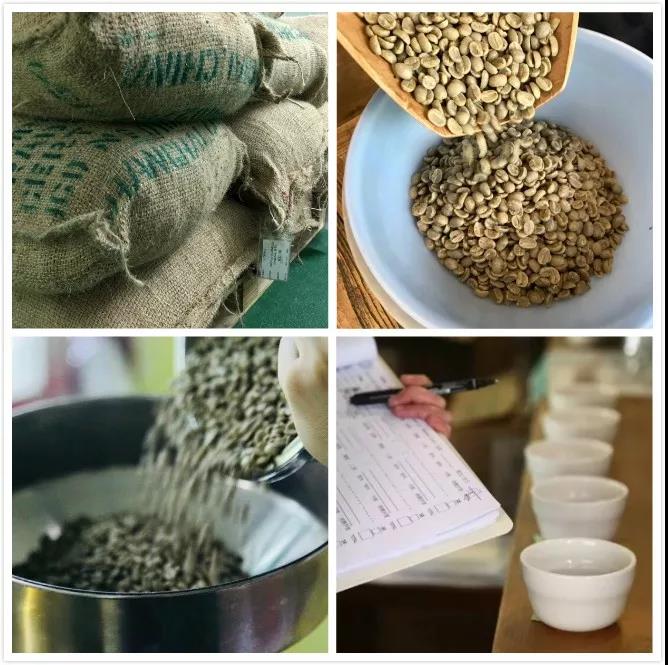

Green Bean Evaluation

Beyond daily roasting and cupping, roasters must perform a crucial task - green bean evaluation. It must be emphasized that coffee isn't ready to sell simply by being roasted. Before us lies the diligent labor of producers; after us awaits the eager anticipation of customers. Therefore, green beans are particularly important. Roasters must not only showcase the best flavors of coffee but also have comprehensive understanding of each batch of incoming green beans.

1 | Comparative Analysis

For small-batch green bean purchases, we should conduct comparative roasting of old versus new stock, using identical roasting methods, then cup to determine whether flavor characteristics remain consistent. If differences exist, roasting adjustments must be made to strive for flavor consistency. However, if a particular coffee cannot maintain its previous quality for various reasons (especially micro-lots or small estate coffees), then the next step is necessary.

2 | Bean Sourcing

Large green bean merchants can travel to producing regions and estates to source beans, but as end-users, our sourcing approach is relatively "low-cost" - by understanding the coffee's origin, altitude, soil, cultivation and post-processing methods, we purchase beans with similar characteristics and flavors for comparative roasting to find suitable substitutes. This process is another battle between alchemists and dishwashers (omitting ten thousand words here).

3 | Bulk Inspection

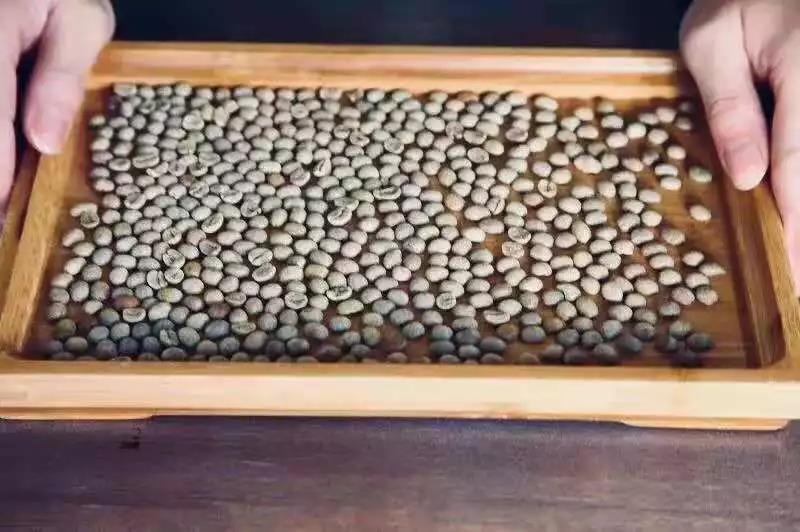

When several large bags of coffee beans arrive, roasters must inspect them. First is visual inspection - checking for uniform size, consistent color (moisture content), sampling for defect rates, and so on.

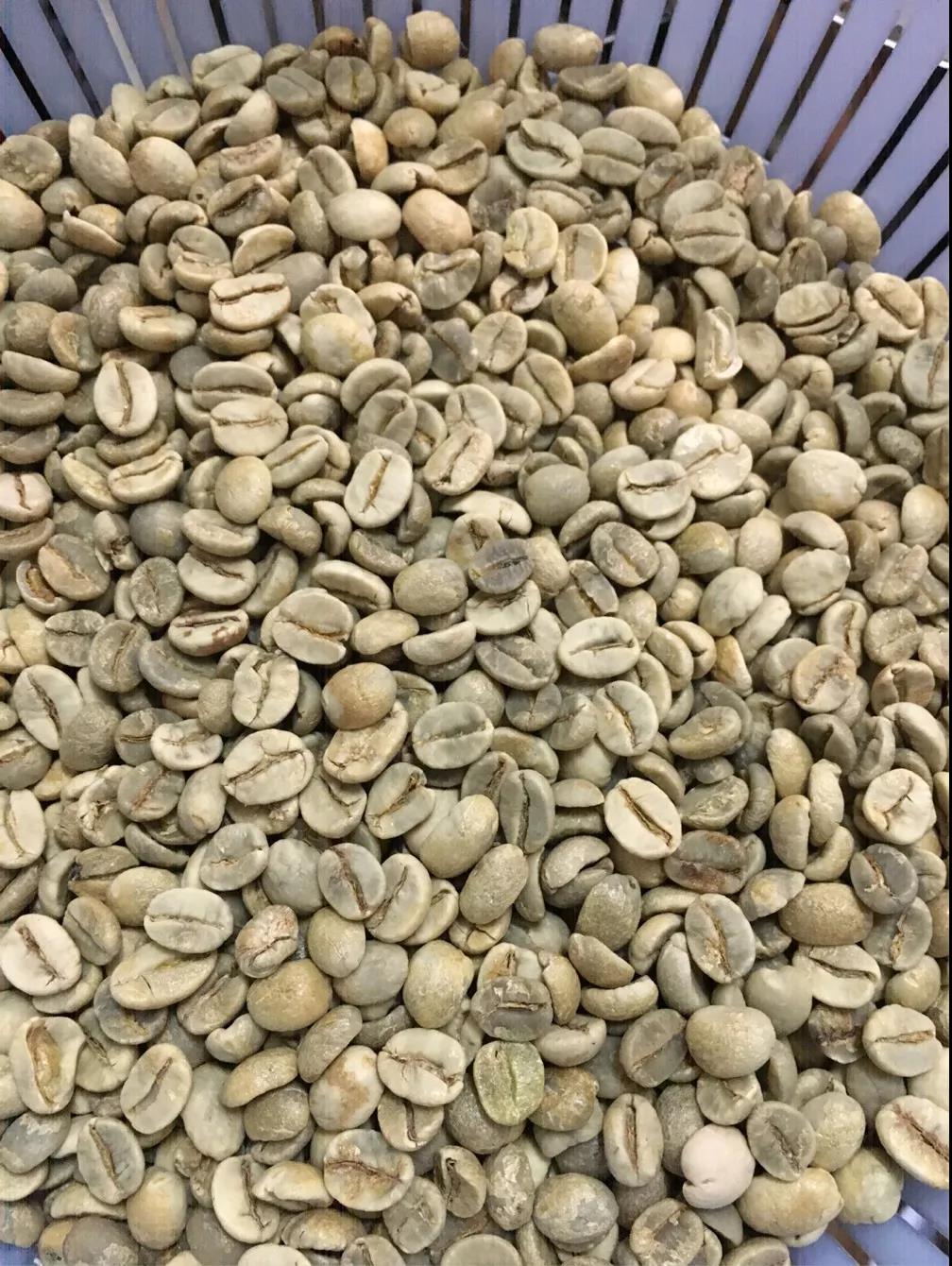

As shown in the image above, although these are the same beans, their moisture content varies significantly, clearly indicating mixed-grade sales. When such green bean conditions are discovered, a return warning should be issued - excessive moisture content differences will cause uneven roasting and无法保证品质 - both green bean merchants and end-users should be responsible for industry integrity and stable, prosperous development.

Additionally, some mixed bean situations involve blending normal quality beans with lower-grade ones. We must conduct sample roasting and cannot be careless!

Sometimes to conceal the truth, normal quality beans may be stacked on top while poorer beans are mixed below. We need to conduct "in-depth" inspection - taking 1/3 of green beans from upper, middle, and lower layers respectively for mixed roasting, then observing whether bean shape and color are consistent.

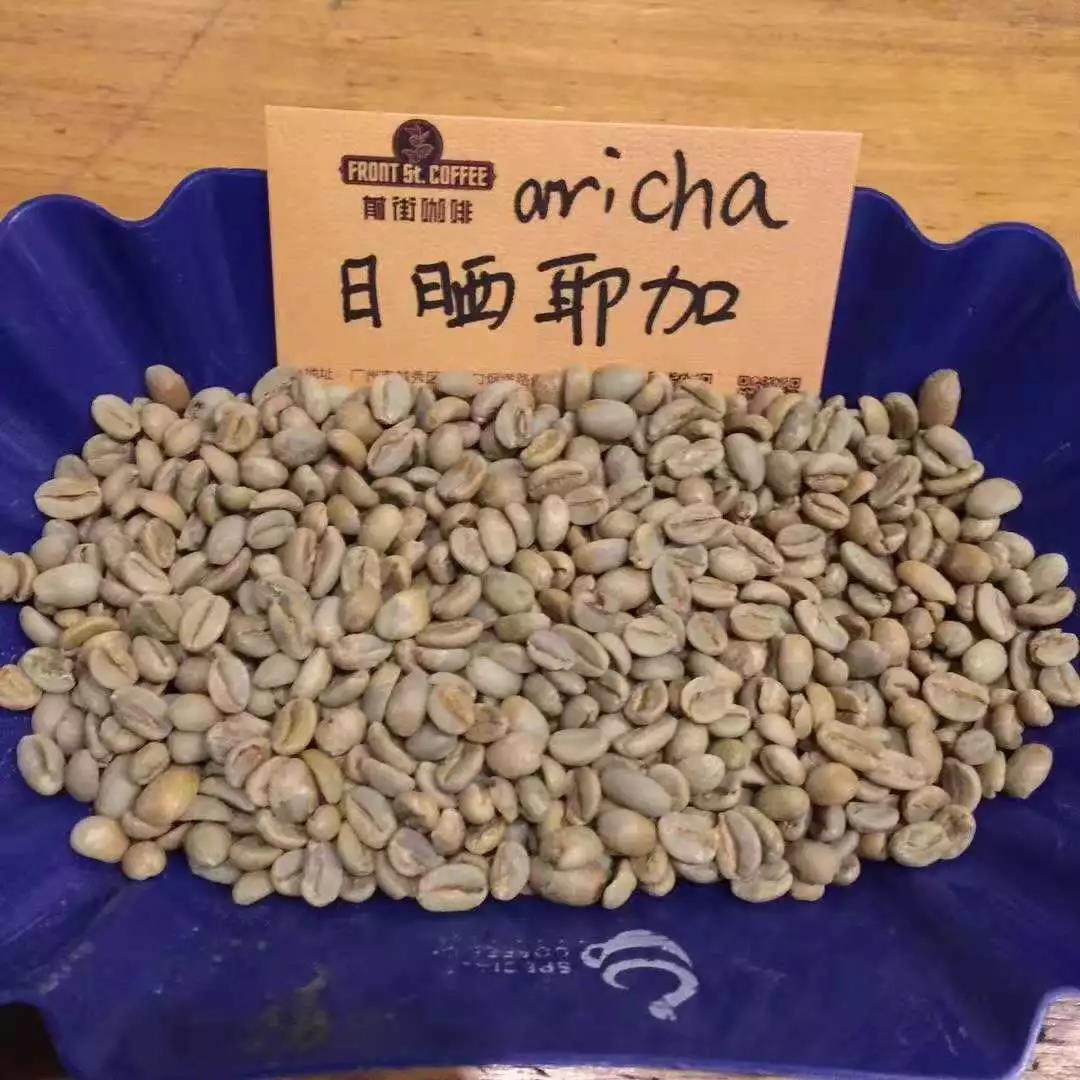

There are some exceptions, such as African Ethiopian coffees graded by green bean defect rates, where bean sizes may vary due to the numerous varieties, which is also the source of their rich flavors. The roasted beans may show some degree of color unevenness, but as long as it's not significantly different (for example, some developing well while others are wrinkled or have cracked center lines turning black), and cupping confirms correct flavors, this is normal. Roasters must clearly understand the grading systems of producing regions and ultimately make objective analyses through roasting and cupping.

Through the discerning evaluation and sensory adjustment by roasters and baristas, a cup of specialty coffee finally presents itself before everyone.

The above represents the meaningful daily routine of our boiler workers.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Review | Comparison of Flavor Characteristics of 3 Kenyan Coffees | How to Brew Kenyan Coffee by Hand?

For professional coffee knowledge exchange and more coffee bean information, please follow Coffee Workshop (WeChat official account: cafe_style). African coffee origins are known worldwide for their captivating acidity and aroma, and Kenya is certainly no exception. Kenya belongs to tropical growing regions with two rainy seasons annually, allowing for two harvests, with 60%

- Next

Banchi Maji | Gesha Village | 2018 Geisha | Honey Process | Ethiopian Gesha

Professional coffee knowledge exchange for more coffee bean information, please follow Coffee Workshop (WeChat official account: cafe_style) [Growers Reserve] Gesha Village Honey Gesha Lot 18/032 Red Label Batch Ethiopia Gesha Village 32 Gesha Variety Honey Process Cupping notes: When ground, reveals lemon peel, apricot, bergamot, and jasmine floral notes. At first sip, experience lemon

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee