What Are the Taste Differences Between the Same Coffee Beans Processed with Washed vs. Natural Methods?

For professional coffee knowledge exchange and more coffee bean information, please follow Coffee Workshop (WeChat public account: cafe_style)

Understanding Coffee Processing: The Fermentation Connection

First, we must clarify a concept: processing = fermentation.

Coffee bean processing refers to the transformation of coffee cherries from the tree to green beans ready for roasting. This process can also be viewed as the fermentation of coffee beans. Just as excellent wine requires proper brewing to produce exceptional flavors, processing methods for green beans are similar - they are treatment methods that combine microorganisms with coffee beans through fermentation, which can guide out the hidden secret flavors of coffee beans!

Secret Flavors of Natural vs. Washed Processing

Natural Processing Method

Natural processing is the oldest method. According to literature records, Arabs as early as the 11th century (over 1000 years ago) began using natural processing to handle coffee fruits. Because of coffee's stimulating effects, when coffee was introduced from the Arab world to the West, it was called "the wine of the Arabs."

Natural Coffee Bean Processing Steps:

1. Removing floating beans

Coffee beans are poured into large water tanks. Underdeveloped, inferior beans will float to the surface, while mature, full fruits will sink to the bottom. At this point, the floating beans are scooped out from the water surface, completing the floating bean removal step.

2. Sun drying

The coffee fruits are evenly spread out on drying grounds and need to be turned several times daily. This process typically lasts about 2-3 weeks, depending on local climate. When the moisture content inside the coffee beans drops to 10-14%, the sun drying step is complete.

3. Removing the outer shell

After sun drying is complete, the outer layer of the coffee seeds has become dry and hard. At this point, a hulling machine is used to remove the outer shell, completing the natural processing steps.

Advantages:

Natural processing doesn't require water except for the floating bean removal step (some regions even skip this step), and one bucket of water can be reused. It's low-cost, so it's widely used in areas with limited water resources and less affluent regions.

Disadvantages:

1. Since natural processing requires coffee beans to be placed outdoors for extended periods, there are often impurities mixed in such as dead branches and fallen leaves.

2. Because it relies on solar energy, the drying degree of coffee beans is difficult to control, leading to "over-drying" situations where coffee fruits get damaged, causing internal coffee beans to break.

3. During the sun drying process, because the pulp is not removed, mold and rot often occur.

Flavor Profile:

Because natural processing allows coffee fruits to dry naturally, coffee beans can naturally mature inside the fruit without interference from the external environment. Therefore, naturally processed coffee beans amplify their inherent flavors, with rich body, strong flavor, and emit sweetness with abundant tropical fruit flavors.

Washed Processing Method

Due to the many disadvantages of natural processing, the washed processing method was invented. Washed processing is currently the most widely used processing method. The biggest difference from natural processing is the use of fermentation to remove the mucilage layer.

Washed Coffee Bean Processing Steps:

1. Removing floating beans (same as natural method)

Coffee beans are poured into large water tanks. Underdeveloped, inferior beans will float to the surface, while mature, full fruits will sink to the bottom. At this point, the floating beans are scooped out from the water surface, completing the floating bean removal step.

2. Removing skin and pulp

Using a pulping machine, the outer skin and pulp of the coffee fruit are removed (leaving mucilage, parchment, and silver skin).

3. Fermentation

The purpose of this step is to use biological treatment methods to remove the mucilage. The coffee fruits processed by the pulping machine are placed in fermentation tanks for 16-36 hours, where fermentation bacteria dissolve the mucilage.

4. Washing

After fermentation and mucilage removal, fermentation bacteria and impurities remain on the coffee beans, so the beans are washed again. To ensure thorough cleaning, this step consumes large amounts of fresh water.

5. Drying and removal of parchment and silver skin

Usually, machines (or sun drying) are used to dry the coffee fruits until moisture content drops to 10-14%. Then a hulling machine is used to remove the remaining parchment and silver skin, completing the processing.

Advantages:

1. All processing steps in the washed method are done indoors, so impurities in coffee beans can be minimized to achieve the highest quality.

2. Since the pulp is removed at the beginning, there's no need to worry about mold problems as with natural processing.

3. The appearance is more complete, with excellent market appeal.

Disadvantages:

1. The process is complex and tedious, so costs are much higher than natural processing.

2. It requires large amounts of fresh water - to obtain 1 kilogram of coffee beans, 40-50 liters of fresh water are needed, so it's less used in water-scarce regions.

Flavor Profile:

Due to fermentation, coffee beans usually have bright acidity and fruit aroma. Sometimes washing can better highlight the unique flavors of the coffee beans themselves.

How Processing Methods Affect Coffee Bean Flavor

Have you grasped the key points?

The answer is: fermentation time and fermentation degree

Natural processing, because beans are sun-dried with skin and pulp together, has a higher degree of fermentation and longer time, usually developing more tropical fruit flavors.

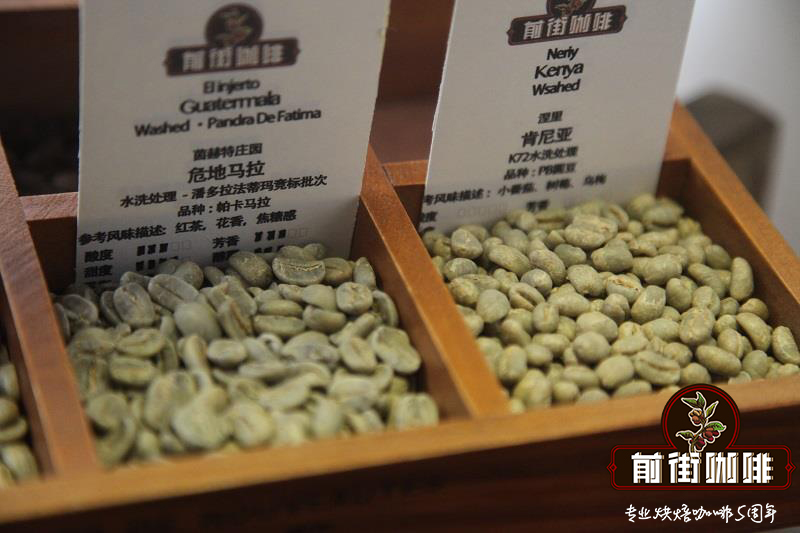

Washed processing leaves only a thin layer of mucilage, and the overall processing time is shorter. Even with the Kenyan 72-hour washed method, there's still a significant time difference compared to natural processing which takes a month. Therefore, it's understandable that generally washed processed beans have cleaner flavors.

Washed processing adds fermentation steps and is cleaned more thoroughly, resulting in refreshing taste with increased acidity. Natural processing retains some pulp, adding berry flavors with a more viscous and full-bodied taste. For African beans, the sweetness is also good, but off-flavors can easily occur.

There is no direct relationship between flavor and green bean processing methods. Naturally processed beans, after a longer aging period (with proper storage), can still capture the transparent, clean, bright acidity of washed beans. Today, some washed beans like Red Cherry also have strawberry and nectarine flavors similar to what we traditionally associate with natural processing. Bean variety and proper roasting methods often determine the final flavor profile of a bean, while different processing methods determine the intensity at which certain elements in the flavor profile are presented during a specific optimal tasting period. The optimal tasting period for naturally processed beans is the second five days after roasting, while the optimal tasting period for washed beans is longer.

Recommended Natural Processed Coffee Brands

FrontStreet Coffee's freshly roasted single-origin natural processed coffee beans - such as natural Yirgacheffe and natural Sidamo coffee - have full guarantees in both brand and quality, suitable for brewing with various equipment. More importantly, they offer excellent value for money. A half-pound (227g) bag costs only about 70-90 yuan. Calculating with 200ml per cup of single-origin coffee and a 1:15 powder-to-water ratio, one bag can make 15 cups of specialty coffee, with each cup costing only about 5-6 yuan. Compared to cafes that sell single-origin coffee for dozens of yuan per cup, this offers exceptional value for money.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

How to Differentiate Natural Coffee Beans_A Guide to the Appearance and Flavor Characteristics of Natural Coffee Beans

Professional coffee knowledge exchange. For more coffee bean information, please follow Cafe Style (WeChat public account: cafe_style). On coffee packaging and in coffee bean introductions, we often see processing method names such as Natural, Washed, Semi-Washed, and Honey. If you're a coffee lover, do you understand these processing methods and their differences?

- Next

How to drink Mexican coffee? Is Mexican coffee good? What are the ways to drink Mexican coffee?

Professional coffee knowledge exchange For more coffee bean information Please follow Coffee Workshop (WeChat official account cafe_style) Around the 6th century AD, an Arab shepherd named Kaldi secretly observed his goats while herding and found that after eating the red fruits of a wild shrub on the hillside, they became unusually excited. Curious Kaldi personally picked these fruits and tasted them, discovering

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee