Too Many Numbers, Overwhelming! How to Actually Read Roast Curves?

What is Coffee Roasting?

Roasting is a heating process for coffee beans. Unroasted green beans have only a slight grassy aroma and subtle fruit fragrance, with almost no taste when consumed. Through the heating process, roasting triggers a series of complex chemical changes within the beans, thereby releasing the various flavor characteristics that were originally locked inside the green beans.

Every time we roast a batch of beans, we record the roasting curve - the return temperature point, heat level, temperature, first crack time, and more. Why record this data? It's to replicate the same coffee flavor based on previous numerical references, maintaining consistency in taste. The key data includes the coffee bean temperature curve, ambient temperature curve, and rate of rise curve. Understanding of the beans can be enhanced through measuring color changes, airflow, and gas pressure.

Key Points to Monitor During Roasting

Preheated Drum Temperature

Before adding beans, we always maintain the drum temperature at a stable value. The drum temperature is detected by the temperature probe inside the roasting chamber. For drum roasters, this probe is typically located on the opposite side of the bean temperature probe and doesn't contact the beans. Some roasters don't have a drum temperature probe and use the temperature at the roasting drum's exhaust port as the drum temperature.

Heat Level

The heat level directly affects the roast degree of coffee beans, their flavor, and our desired roasting time. Higher heat levels produce more flavors, but not all flavors are necessarily good. Sufficient heat allows coffee beans to release more flavor compounds, but it also highlights undesirable flavors in the beans. Therefore, throughout the roasting process, we need to coordinate with the damper to adjust the coffee beans' flavors to their optimal state while ensuring the beans' cleanliness.

Damper Adjustment

In some ways, the damper assists the heat level and stores heat. At the same time, it accommodates the various flavors released by the heat. The damper size affects the heating efficiency of hot air on green coffee beans in the drum. With sufficient heat, slightly opening the damper can enhance the hot air's effect on green coffee beans. However, insufficient heat or an overly large damper opening can cause the drum to lose temperature. When necessary, opening the damper wider can more quickly remove the silver skin and particles that cause off-flavors during coffee roasting. Damper size also affects the drum's pressure, influencing the development of coffee beans.

Return Temperature Point

After beans enter the drum, they immediately absorb heat, causing the drum temperature to drop sharply, then at some point, the temperature rises again. This equilibrium point is the return temperature point.

Yellowing Point

Green beans enter the heat absorption stage. To transfer heat to the bean interior, water conductivity is utilized. If the bean moisture content is low, the time to reach the yellowing point will be shorter. Conversely, if the bean moisture content is high, it will take longer to reach the yellowing point. Water evaporates and converts to steam, increasing internal steam pressure and temperature. At this point, beans begin to expand in structure, destroying chlorophyll and entering the yellowing point.

Maillard Reaction and Caramelization

Maillard Reaction Process

During coffee roasting, the Maillard reaction mainly begins after dehydration is complete, when the bean color starts turning from yellow to brown, and continues until the end of roasting when the beans are completely cooled. The unique aroma of roasted coffee beans combines various flavors including the blue-green smoke smell of burning plant fibers, the sweet cream-yellow fragrance, and the roasted bread brown aroma. Most of these rich flavors come from the Maillard reaction during roasting.

Absorbing large amounts of thermal energy initiates pyrolysis reactions, producing the first cracking sound. Some sugars convert to carbon dioxide, moisture continues to evaporate, and new aromatic compounds gradually develop, forming so-called coffee oils, which combine with hundreds of aromatic substances including nicotinic acid, citric acid, quinic acid, malic acid, acetic acid, and caffeine.

Caramelization Reaction

Sugars in coffee beans undergo caramelization reactions at approximately 170-200°C, which coincides with sucrose's melting point (185°C) and the temperature range during the first crack stage of coffee roasting. The products of caramelization reactions are divided into two parts:

1. Dehydration products of sugars - caramel or sauce color

2. Decomposition products - mainly volatile aldehydes and ketones

Overall, caramelization produces roasted aromas, caramel, and color, as well as other aromatic compounds such as maltol, Cyclotene, and furan compounds. These compounds can also be found in foods like red wine, fruit juice, and cream.

However, over-caramelization during roasting is not a good thing, as it can cause carbonization, making coffee bitter and harsh. Insufficient caramelization results in monotonous and lackluster aromas lacking depth.

Green beans contain many sugars, proteins, and amino acids. A series of changes caused by sugars and amino acids generate brown-black macromolecular substances called melanoidins. Besides producing melanoidins, the reaction process generates hundreds or thousands of intermediate molecules with different odors, including reductones, aldehydes, and heterocyclic compounds. These substances provide pleasant flavors and appealing colors to food.

First Crack

This refers to the obvious and strong sound made by coffee beans in the machine during roasting, somewhat similar to making popcorn or burning wood. When coffee beans absorb enough heat that the pressure from internal moisture evaporation exceeds the bean's structural strength, the cell walls rupture due to inability to withstand the pressure from internal expansion. At this moment, coffee beans emit the first crack sound, releasing thermal and acoustic energy. This is the generation of the "first crack." Different flavor compounds are released (that is, aromatic substances like floral and fruit notes), and browning occurs (which is why coffee beans are brown). This is also when coffee beans undergo significant flavor development. Even a difference of one second earlier or later in dropping the beans can result in substantial flavor variations.

Rate of Rise

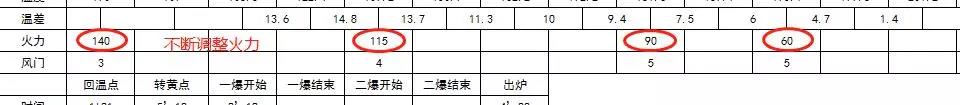

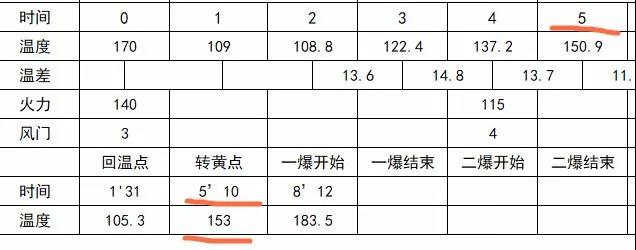

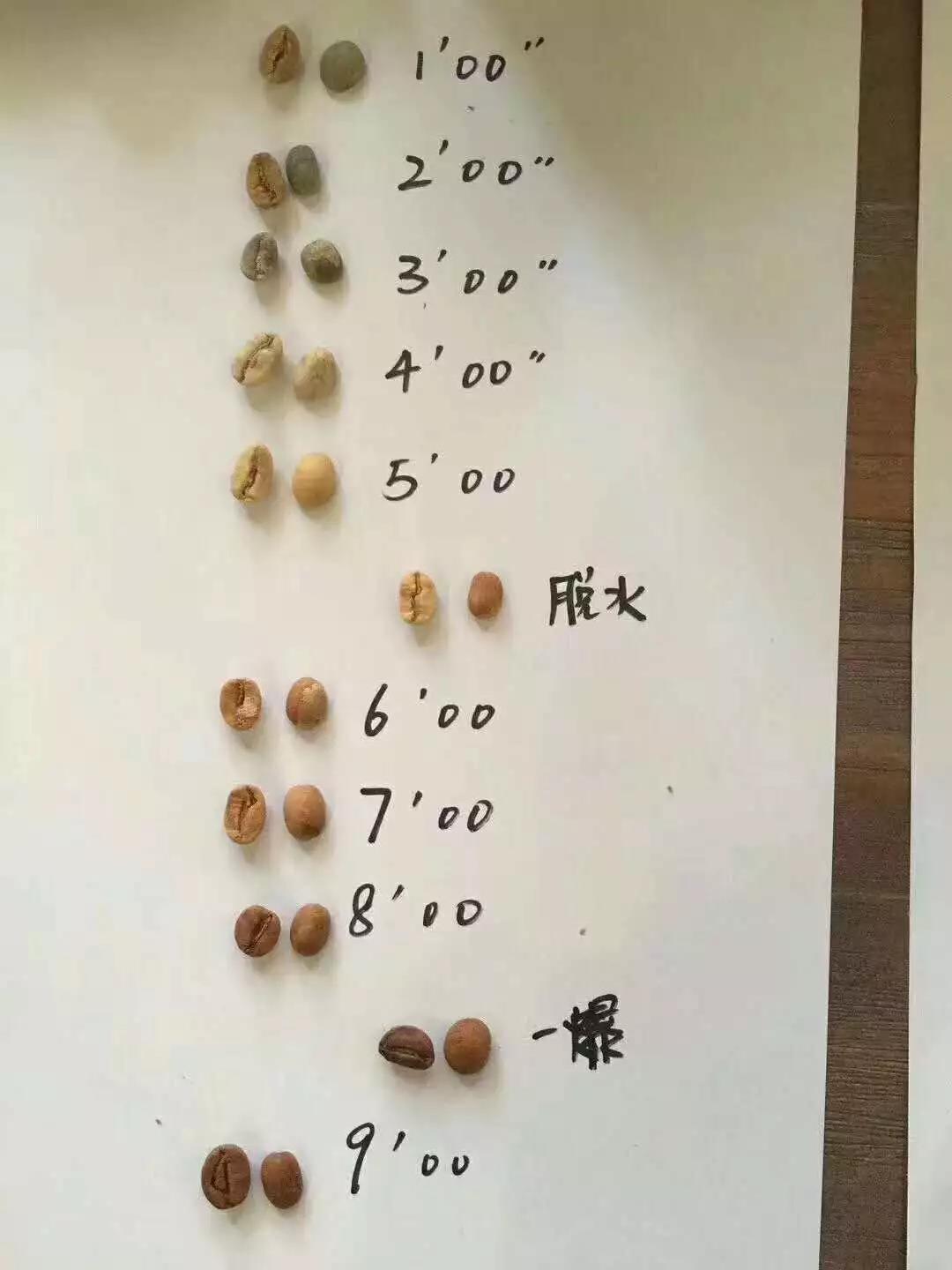

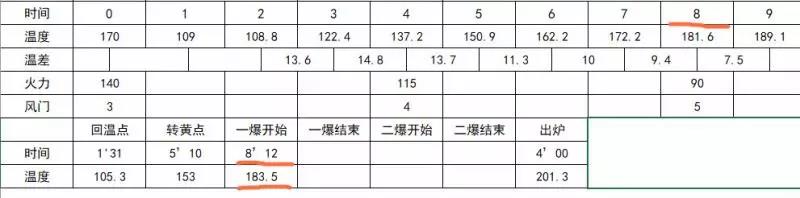

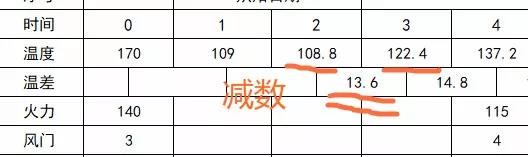

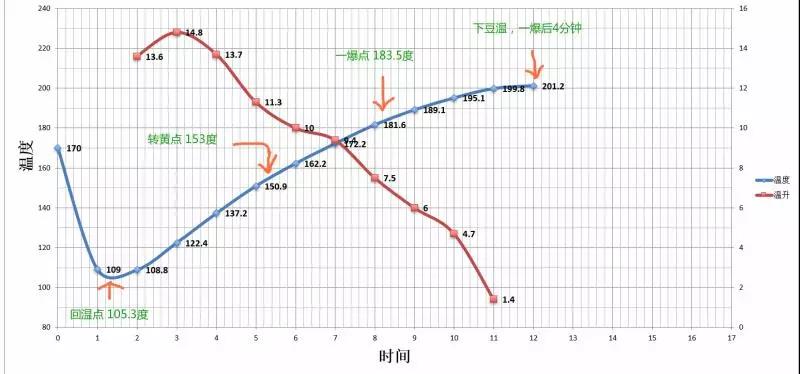

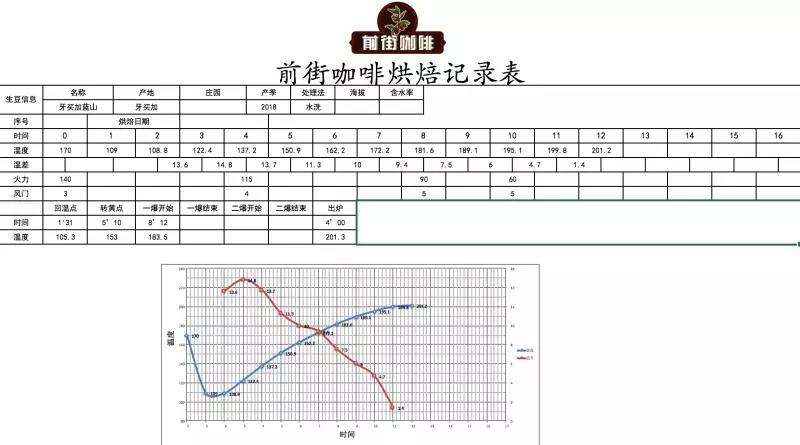

The temperature difference between two time points. For example, between minute 2 and minute 3, there will be a temperature difference. Subtracting the latter (122.4°C) from the former (108.8°C) yields a value (13.6°C).

In designing roasting curves, to roast a batch of beans thoroughly "from inside out," we must use good roasting techniques based on proper roasting foundation. We need to determine at which roasting stage flavors will manifest, how to create more possibilities for this stage, how to balance between controlling flavors and defect flavors, and how to ensure the coffee beans' balance of sweet, sour, bitter, and spicy notes. After the first crack, what heat level should be maintained and for how long should development continue?

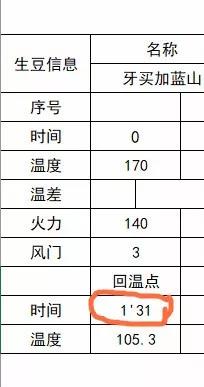

Taking the roasting of [FrontStreet Coffee Jamaica Blue Mountain] as an example, we need to understand this bean's characteristics. [FrontStreet Coffee Blue Mountain] is grown on slopes at 1310 meters elevation, featuring fertile volcanic soil, fresh air free from pollution, humid climate with year-round fog and rain, average precipitation of 1980mm, and temperatures around 27°C. Washed processing involves 12-18 hours of fermentation, then placing the fermented beans in pools and moving them back and forth until the coffee beans are washed smooth and clean, enhancing the stable and delicate acidity of FrontStreet Coffee's Blue Mountain beans. FrontStreet Coffee's Blue Mountain consists of NO.1 beans above 17 mesh, with a defect rate below 3%, moisture content around 13%, and medium bean density, suitable for roasting using a steady progression approach.

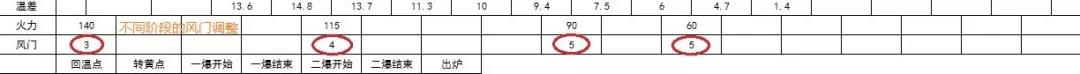

First, preheat the drum to 170°C and add beans with damper opening at 3. After 1 minute, adjust heat to 140°C, keeping damper unchanged. Roast until 5'10", temperature reaches 153°C, bean surface turns yellow, grassy aroma completely disappears, dehydration is complete. Adjust heat to 115°C, damper to 4;

At 8'00", ugly wrinkles and black spots appear on the bean surface, toasted bread aroma clearly transforms into coffee aroma - this can be defined as the prelude to first crack. At this point, listen carefully for the first crack sound. At 8'12", first crack begins, reduce heat to 90°C, fully open damper (heat adjustment must be very careful, not too low to stop cracking sounds), and drop beans at 201.3°C.

This roasting approach achieves a perfect and delicate balance of acidity, body, and aroma. The acidity is bright and delicate, with a velvety smooth texture. The aroma carries slight penetrating qualities, accompanied by floral, spicy, and caramel notes. There's a subtle cocoa aftertaste in the mouth.

The flavor is very clean, complex, and mild, with chocolate sweetness and strong body. The taste is rich and mellow, with perfect combination of coffee's sweet, sour, and bitter notes - completely without bitterness, only moderate and perfect acidity, with persistent fruity finish.

After roasting is complete, cupping evaluation is essential:

Dry aroma: roasted peanuts, hazelnuts, melon, chocolate

Wet aroma: oolong tea, caramel, honey, chocolate, almond skin, silky texture, brightness

Doesn't this make reading roasting curves much clearer? Understanding roasting curves actually reveals the roaster's understanding of these beans. We chose to drop the beans 4 minutes after first crack because we wanted to preserve more of the creamy chocolate, rich brown sugar flavors, and heavy body of [FrontStreet Coffee Blue Mountain]. Today's sharing hopes to help everyone understand curves better~

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

How to Choose Pour-Over Coffee Beans _ Introduction to Pour-Over Coffee Bean Varieties _ What Are the Best Brands of Pour-Over Coffee Beans

Professional coffee knowledge exchange For more coffee bean information please follow Coffee Workshop (WeChat official account cafe_style ) The market is filled with a dazzling array of pour-over coffee beans. If you don't have specific coffee preferences, you'll surely be overwhelmed by the price list. It's recommended to first understand what flavor profile you prefer in coffee—is it heavy floral notes, rich fruity aromas, or a lighter taste—then ask the shop staff for recommendations

- Next

Common Pour-Over Coffee Mistakes_ Best Coffee Beans for Pour-Over Coffee_ Types of Pour-Over Coffee Beans

Professional coffee knowledge exchange For more coffee bean information Please follow Coffee Workshop (WeChat official account: cafe_style) Many people wonder why they still can't brew a delicious cup of pour-over coffee even when following the steps correctly? Now let's uncover the common mistakes in pour-over coffee from the perspective of coffee beans and water quality! Common Pour-Over Coffee Mistakes 1 Coffee Beans Mistake 1: Grind

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee