What is the Red Wine Processing Method for Panama Hartmann Coffee? What is Coffee Anaerobic Fermentation?

Professional Coffee Knowledge Exchange

For more coffee bean information, please follow Coffee Workshop (WeChat official account: cafe_style)

Wine Processing Method

The wine processing method has become a hot topic in the industry. During the processing from coffee cherry to green coffee bean, "fermentation" occurs to varying degrees. Whether it's washed processing, honey processing, or natural processing, all undergo this chemical change process. Different substances participate in fermentation (coffee skin, coffee pulp, coffee pectin, types of bacteria, bacterial distribution), different fermentation environments (with or without water, aerobic or anaerobic, pH environment, etc.), and different drying processes (container material, natural sun-drying, drying equipment, frequency of turning) all contribute to different post-processing flavors and mouthfeel.

Coffee Processing: Wine Processing Method (Also Known as Carbon Dioxide Processing Method)

Also called wine-like processing method, inspired by the brewing process of red wine. Currently, only eight estates in Colombia have successfully brought coffee beans treated with this processing method to market. According to information from these eight estates, we can roughly classify wine processing methods into: acetic acid fermentation (Aerobic fermentation), lactic acid fermentation (Anaerobic fermentation), and mixed fermentation (Mix Fermentation = Aerobic + Anaerobic).

Traditional processing methods make it difficult to control the varying degrees of coffee bean fermentation. However, the wine processing method can ensure coffee bean quality by controlling pH value, and even temperature and humidity, while closed fermentation prevents aromatic substances from volatilizing easily.

Carbon dioxide maceration processing method is a new processing method applied in wine processing, where whole grapes are placed in carbon dioxide gas to enter an anaerobic state. This way, even without yeast, the grape fruit itself will convert its own sugar into alcohol, bringing special aromas. Wine brewed with this method has soft aromas, rich mouthfeel, and stable color.

The earliest time carbon dioxide maceration processing method came to our attention should be 2015 when Sasa Sestic won the world championship with a washed bean processed by carbon dioxide maceration.

How Does This Processing Method Differ from Regular Natural, Washed, and Honey Processing?

Carbon dioxide maceration processing method is a new processing method applied in wine processing, where whole grapes are placed in carbon dioxide gas to enter an anaerobic state. This way, even without yeast, the grape fruit itself will convert its own sugar into alcohol, bringing special aromas. Wine brewed with this method has soft aromas, rich mouthfeel, and stable color.

How to Apply This to Coffee?

1) After removing pulp and skin from coffee beans, place them in stainless steel containers—why choose stainless steel containers? Sasa says stainless steel containers can better ensure clean flavors. Then control different temperatures to affect the reaction speed.

2) Place the stainless steel containers indoors where temperature is easier to control. They found that if more complex acidity is needed in the beans, control the temperature at 4-8°C, while if higher sweetness is needed, control the temperature at 18-20°C.

3) Seal the fermentation tank, which can develop more aromatic substances.

4) This is the most crucial and important step. Add carbon dioxide to the fermentation tank. Carbon dioxide is denser than oxygen, thus squeezing out air. This places coffee beans in an anaerobic environment. Because there is no oxygen, this slows down the decomposition speed of sugar in coffee bean pectin, while the pH value also drops at a slower rate.

With the help of carbon dioxide, the entire fermentation process at 22°C will be extended by 3 days, and if the temperature is lower, the fermentation time can be longer. This reduces astringent mouthfeel and acetic acid flavors. During the entire fermentation process, like Tim, Sasa constantly records these pH values, fermentation temperature, and carbon dioxide amounts are completely recorded, hoping to make corrections and replications in the future.

FrontStreet Coffee's Panama Hartmann

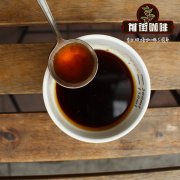

FrontStreet Coffee's Panama Hartmann uses this processing method. The wine processing method gives this bean a rich fermented wine aroma that is truly surprising!

FrontStreet Coffee Pour-over Recommended Parameters:

V60/90°C/1:15/Time two minutes

Flavor:

Grapefruit, low acidity, rich fermented wine aroma

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

What is Panama Hartmann Coffee Red Wine Processing? What are Coffee Bean Processing Methods?

Professional coffee knowledge exchange For more coffee bean information please follow Coffee Workshop (WeChat official account cafe_style) After coffee is planted and harvested the next step is processing. Previously it was mostly dominated by natural and washed processing then honey processing became popular and was divided according to the pulp retention ratio: black honey red honey yellow honey white honey each with different flavor characteristics.

- Next

Yemen Mocha Coffee Beans Origin | How to Brew Mocha Coffee Beans Video Tutorial | Mocha Coffee Beans Price

Professional coffee knowledge exchange. For more coffee bean information, please follow Coffee Workshop (WeChat public account: cafe_style). Yemen Mocha Coffee Beans Coffee Origin Introduction: Yemen produces peaberry coffee beans: These coffee beans are smaller and rounder than most coffee beans, resembling peas, and are sometimes referred to as Mocha coffee beans. The appearance of Mocha coffee beans is also different from

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee