Complete Guide to Coffee Bean Roasting: Comparison Chart of Eight Coffee Roast Levels and Their Differences - Medium vs Dark Roast Distinctions

Regular coffee drinkers know that coffee beans come in different roast levels, each presenting distinct flavors and mouthfeel. As a coffee shop with in-house roasting, FrontStreet Coffee roasts dozens of batches of coffee beans daily, from light-roasted Yirgacheffe to medium-roasted Brazilian coffee, understanding their flavors intimately. We also need to adjust roasting curves for new beans, as coffee roasting is indeed a profound craft. Now, let FrontStreet Coffee share our understanding of roasting!

Coffee roasting refers to the process of heating raw beans to promote a series of physical and chemical reactions inside and outside the coffee beans, generating multiple flavors such as acidity, bitterness, and sweetness during this process, forming body and color, and transforming raw beans into dark brown beans.

The most important aspect of coffee roasting is consistency, which means the repeatability of roasting.

For buyers, the biggest fear is inconsistent coffee quality. For example, the flavor of the same beans might be completely different from last time, despite using the same brewing method, yet the flavors are worlds apart. This is when the roaster's ability is tested. The phrase "quality consistency" sounds simple but is actually difficult to achieve in practice.

FrontStreet Coffee believes we cannot ignore the fact that there are too many factors that can affect roasting results. Besides uncontrollable factors like raw beans and weather, other factors requiring human adjustment include: flame adjustment, whether the air damper is cleaned properly, gas usage, etc. To achieve stable roasting of beans, the roaster must record detailed information for each batch: bean entry temperature, bean entry weight, bean return temperature point, drum temperature per minute, dehydration point, first crack point, first crack time, discharge time, dehydration rate, temperature rise rate, etc. (the more detailed, the better). Because slight changes in temperature and heat during roasting can alter the beans' flavor, different beans have different characteristics, and roasting is a quick operation completed in a short time, it requires accurate prediction of the roasting process and curve correction through cupping.

Types of Coffee Roasting Machines

Before learning coffee roasting, let's look at the most common types of coffee roasting machines:

- Direct Fire Roaster

- Half Hot Air Roaster

- Hot Air Roaster

Before starting roasting, let's understand the basic structure of roasting machines. FrontStreet Coffee uses a Yangjia Feima 600g roaster (Half Hot Air Roaster).

Detailed Explanation of Coffee Roaster Types:

1. Hot Air Roaster

Hot air roasters use blowers to draw in air, then pass it through a heating coil to increase its temperature, using hot air as the heat source to roast coffee beans. Hot air not only provides the necessary temperature for roasting but also uses airflow power to tumble the coffee beans, achieving two goals at once.

Advantages: High thermal efficiency, fast heating, relatively even heating of raw beans, easy to control.

Disadvantages: Because of high heating efficiency, it's easy to cause temperature to rise too quickly, resulting in beans being "under-roasted," and excessive temperature can lead to insufficient caramelization reaction.

Flavor characteristics: Obvious acidity, relatively clean and simple taste, but lacks flavor richness and depth, and dark roasting can easily produce irritating flavors.

2. Direct Fire Roaster

As the name suggests, direct fire roasting uses flames to directly heat coffee beans. Evolved to this day, the "fire" in direct fire includes not only ordinary flames (including gas stove flames and charcoal fire) but also infrared rays and electric heating tubes.

Advantages: Longer roasting time allows for more complete caramelization, resulting in richer flavors.

Disadvantages: Easily causes uneven roasting, and poor fire control can easily burn coffee beans, creating bitter flavors.

3. Semi-Direct Fire Semi-Hot Air Roaster

This roasting method combines the advantages of both direct fire and hot air roasters and is currently the mainstream for commercial roasting machines. Semi-direct fire roasting is actually quite similar to direct fire roasting, but because there are no holes in the outer wall of the roasting container, the flame doesn't directly contact the coffee beans. Additionally, it includes exhaust equipment to bring hot air outside the roasting container into the roasting chamber to improve roasting efficiency. Another function of this exhaust equipment is to suck out the silver skin (a thin film attached to the outside of coffee seeds), preventing it from burning in the roasting chamber at high temperatures and affecting the coffee beans' flavor.

Semi-direct fire semi-hot air machines have both the advantages and disadvantages of direct fire and hot air types, but can change their heating method by adjusting hot air and drum rotation speed. The larger the hot air setting and the faster the rotation speed, the closer it is to hot air roasting; conversely, the closer it is to direct fire roasting.

This type of home roaster uses alcohol lamps or gas lamps as heat sources, while larger ones use flames directly on gas stoves as heat sources. The advantage of this roaster is its intuitive nature, making it easy to control the roasting degree, and silver skin cleanup is convenient, but roasting temperature is not easy to control.

How FrontStreet Coffee Operates Hand-Cranked Semi-Direct Fire Drum Roaster

- Fill the roasting drum with raw coffee beans, with the amount depending on the drum size, then seal the drum.

- Ignite the heat source, crank the handle at a steady speed, turning the roasting drum to ensure even tumbling of the beans inside.

- After 3-4 minutes of roasting, the beans in the container begin to turn yellow, silver skin separates, and aroma is released.

- When roasting reaches 6-7 minutes, the beans in the container have turned brown and begin to emit white smoke. First crack starts around 8 minutes.

- At about 10 minutes, first crack ends. If you prefer a light flavor, you can discharge the beans now. Otherwise, continue roasting and wait for second crack.

- At 12 minutes, second crack is complete. Quickly discharge the beans and cool them with an electric fan. Roasting is complete.

How FrontStreet Coffee Determines Coffee Roast Level

Raw Beans: Each coffee cherry contains two raw beans, with aroma still hidden deep within, waiting to be discovered. Raw beans contain large amounts of chlorogenic acid, which gradually disappears during the roasting process, releasing familiar and pleasant fruit acids—such as acetic acid, citric acid, and malic acid found in wine. Proper roasting can appropriately present these wonderful acids; conversely, excessive roasting will completely mask them.

During 5-7 minutes of roasting, beans begin to release moisture, changing from light green to orange-yellow, emitting a unique aroma similar to roasted vegetables with cream.

Light Roast: When the beans emit the first light crack and simultaneously expand in volume, changing to an appetizing cinnamon color, it's also called cinnamon roast or half-city roast. Acidity dominates the flavor of light-roasted beans, and the texture and mouthfeel haven't fully developed, so they're generally used for canned coffee and cannot satisfy true coffee connoisseurs.

Light roasted coffee beans

Medium Roast: At 10-11 minutes of roasting, coffee beans present an elegant brown color. New Yorkers like to start their day with medium-roasted coffee beans, adding rich milk and sugar at breakfast, so this roasting method is also called breakfast roast or city roast. Medium roasting preserves the original flavor of coffee beans while appropriately releasing aroma, making it the preferred choice for single-origin coffees like Blue Mountain, Colombian, and Brazilian.

Medium roasted coffee beans

At 12-16 minutes, oils begin to surface, and the beans are branded with deep, oily brown by the intense fire, called full-city roast. Some believe this is when coffee's acidity, sweetness, and bitterness reach the most perfect balance point, and the coffee bean's character is distinctly outlined.

Dark Roast: The darker the coffee beans' color, the sweeter and more mellow the flavor becomes. At this point, when oils have caramelized, the bitterness turns to sweetness with endless aftertaste, making it most suitable for brewing strong Espresso coffee, so it's also called Italian roasting.

Proper roasting gives coffee beans life, transforming them into intriguing acidity, sweetness, and bitterness upon tasting. However, people sensitive to caffeine might want to choose dark-roasted beans, because during the roasting process, caffeine gradually dissipates, so the darker the roast, the lower the caffeine content. It's said that the caffeine content in each cup of Espresso is only half that of other medium-roasted single-origin coffees.

Dark roasted coffee beans

We all know that during the roasting process, coffee beans produce coffee flavor and aroma. So, how are these flavors and aromas obtained? What is their relationship with caramelization and Maillard reactions?

What is Caramelization Reaction?

The sugar in coffee beans undergoes caramelization reaction at approximately 170-200°C, which coincides with the melting point of sucrose (185°C) and the temperature during the first crack stage of coffee roasting.

The products of caramelization reaction are divided into two parts:

- Dehydration products of sugar, namely caramel or sauce color.

- Decomposition products, mainly some volatile aldehydes and ketones.

Overall, caramelization reaction produces roasted aroma, caramel and color, as well as other aromatic substances such as maltol, Cyclotene, furan compounds, etc. These compounds can also be found in foods like red wine, juice, and cream.

However, excessive caramelization during roasting is not a good thing, as it can cause carbonization, making coffee harshly bitter and throat-irritating. Insufficient caramelization will result in monotonous and lacking aroma with no layers.

Caramelization reaction temperature and coffee roasting

During the roasting process, three elements that determine the final flavor of coffee must be properly controlled: acidity, sweetness, and bitterness. Generally, the longer the total roasting time, the less acidity remains, while bitterness increases with longer roasting, making darker roasted coffee more bitter.

It's such a seemingly uncomplicated process that sublimates sugar, breaking the singular sweetness and incorporating a more seductive color and a more appetite-stimulating aroma. If you simmer sugar at home, the entire process is accompanied by intoxicating aroma.

What is Maillard Reaction?

Maillard reaction is the most complex chemical reaction that occurs during coffee roasting, without exception! After Maillard reaction, the flavor substances in coffee beans are more than double those in raw beans before roasting! Therefore, Maillard reaction is one of the main reactions that produce coffee's myriad flavors.

Maillard reaction refers to the series of complex reactions where amino compounds (amino acids and proteins) and hydroxyl compounds (mainly reducing sugars like glucose, fructose, lactose, maltose, etc.) generate brown compounds and later produce black macromolecular compounds—melanoidins. Therefore, Maillard reaction is also called non-enzymatic browning reaction.

Maillard Reaction Process Can Be Divided Into Three Stages:

1. Initial Stage:

Carbonyl-amine condensation, Amadori molecular rearrangement

2. Middle Stage:

Amadori molecular rearrangement product fructosamine dehydrates to HMF (hydroxymethylfurfural)

Fructosamine loses amino group to form reductone

Amino acids react with dicarbonyl compounds

3. Final Stage:

Alcohol-aldehyde condensation

Polymerization reaction producing melanin

During coffee roasting, Maillard reaction mainly begins after dehydration is complete when the bean color starts changing from yellow to brown, and the reaction continues until the end of roasting and the beans are completely cooled. However, when first crack is about to begin, another reaction important to coffee flavor—caramelization reaction—will start, and it will share the same raw material as Maillard reaction—sugar, causing the Maillard reaction rate to slow down around first crack. Therefore, the main Maillard reaction stage generally refers to the period from when coffee beans turn yellow to first crack during roasting. During the reaction process, macromolecular compounds like melanoidins are continuously produced, and through the reaction, more than 600 volatile organic compounds will exist in roasted coffee beans. So Maillard reaction brings flavor, mouthfeel, color, and complexity to coffee.

Therefore, during coffee roasting, the degree of Maillard reaction can be indirectly adjusted by adjusting the roasting rhythm, thereby adjusting coffee flavor. Since increasing temperature after 80°C has little effect on Maillard reaction rate, it's generally adjusted by extending or shortening reaction time. Extending Maillard reaction time will produce more macromolecular melanoidins, bringing heavier mouthfeel, more complex, and deeper-toned flavors to coffee.

About First Crack and Second Crack

As roasting progresses, the bean temperature begins to rise.

First Crack: The components in coffee beans begin to undergo various chemical changes, gradually forming the coffee beans' color, bitterness, acidity, and aroma. At this time, water vapor and carbon dioxide gradually form inside the beans. These gases increase the internal pressure of coffee beans, causing them to expand. Because the structure cannot withstand the increasing pressure, coffee bean cells are damaged with crackling sounds—this is the so-called "first crack."

Second Crack: After first crack, some components begin to decompose while generating heat. This process produces gases, causing the beans to continue expanding. With the expansion of coffee beans, cells are damaged again, followed by crackling sounds. This is the so-called "second crack" or "third crack." This change only stops when coffee beans are removed from the roaster and forcibly cooled.

Once coffee beans expand, they won't shrink back. When roasting raw coffee beans of the same variety, the bean size determines whether deep or light roasting is used—lightly roasted coffee beans are smaller in size.

Common Problems in Coffee Roasting Stages:

- Insufficient preheating temperature, beans enter immediately, extending roasting time. This results in high roasting loss, light bean color because insufficient heat prevents surface from fully caramelizing, lacking color and creating rough internal texture.

- Too high roaster temperature, forming hard crust too early during roasting, suppressing internal expansion. Because the surface colors faster, operators mistakenly think the product is ready and end roasting prematurely. These beans have sticky and dense interiors, failing to achieve proper expansion and lacking normal aroma.

- Too long idle time after preheating. Dry heat for too long causes too much heat to accumulate in the internal chamber. When beans enter, all heat sources concentrate on the bean surface in the initial roasting stage, creating too strong initial heat, followed by rapid temperature drop. Unstable internal temperature makes it difficult for coffee beans to cook internally.

- Roasting time too long or too short. Roasting temperature and duration should be adjusted according to bean quantity. Small quantities have more roasting chamber space, with greater thermal conduction and radiation from metal, so temperature should be lower; larger quantities can use higher temperature. Roasting duration also needs flexible adjustment. Beans generally absorb heat from surface and surroundings to transfer to the center, so roasting conditions can be observed through external changes.

- Different types and performance of roasting machines also cause differences in roasting time and temperature. From traditional direct-fire gas up-down heating to commonly used electric heating today, energy convection design is continuously improved. Additionally, adding fans enhances stable thermal convection, making roasted bean colors more uniform while saving electricity and roasting time.

Key Points to Consider Before Roasting Coffee Beans:

Remove defective beans mixed in with raw beans, as even one defective bean can affect the flavor of the entire batch.

The ideal moisture content for raw beans is 11-13%. Maintaining this moisture level requires good storage conditions—warehouse humidity and temperature should ideally be maintained at an average of 50% and 20°C respectively.

When preparing to roast, we measure the required weight of raw coffee beans and pour them into the machine's hopper. Although they're ready for roasting, sometimes they might wait in the hopper for a while. Why? Because before roasting, the roasting machine needs preheating. We set the target preheating temperature, and after preheating reaches the appropriate drum temperature, raw beans can be loaded. This principle is similar to pan-frying steak—we rarely place a steak on a cold pan. Using an oven to bake cakes—preheated ovens bake cakes more evenly and expand better. Coffee roasting and cooking share similar principles: both require preheating tools.

Raw beans diagram

Key One: Preheating

Reference the basic bean entry temperature of 200°C for the roasting machine used, so first let the drum temperature stabilize above 200°C. Set the air damper to maximum, preheating time is about 30-45 minutes. After 45 minutes, temperature reaches 200-210°C, and preheating is complete.

If the drum temperature is 210°C and we need 200°C for bean entry, we can close the air damper to drop the temperature to 200°C, then proceed to the next step—bean loading. Rapid temperature increase is not recommended, because in roasting machine results, excessive heat (gas volume) only increases the drum surface temperature, not the entire drum temperature.

Key Two: Determine Bean Entry Temperature Based on Raw Bean Properties

Today's reference is Papua New Guinea Bird of Paradise, Typica variety, low-density raw beans, not suitable for dark roasting, with natural refreshing acidity and fruit aroma. We'll choose medium-light roasting, focusing on fire adjustment after first crack. First, assess the raw bean conditions and determine roasting method. It's a washed-process, low-density, 10% moisture content 17-year-old raw bean. Based on existing raw bean state, set entry temperature to 200°C.

Key Three: Heat Adjustment

The roasting process is tricky—too much heat causes outside-cooked inside-raw; too little heat causes over-roasted inside. Consistent roasting inside and out requires proper heat control.

FrontStreet Coffee's Specific Roasting Operations

Drum temperature to 200°C for bean entry, air damper set to 3. After 1 minute of steaming, adjust heat to 160°C, air damper unchanged. When drum temperature reaches 160°C, adjust heat again to 115°C. Roast to 5 minutes 35 seconds, temperature 152°C, bean surface turns yellow (Maillard reaction begins), grassy smell completely disappears, dehydration complete. Adjust air damper to 4 (water vapor produced at this time, open larger damper to discharge water vapor).

At 9 minutes, bean surface shows ugly wrinkles and black spots, toasted bread aroma clearly changes to coffee aroma—this can be defined as the prelude to first crack. Listen carefully for the first crack sound. At 8 minutes 40 seconds, first crack begins. Keep small heat unchanged, air damper fully open to 5 (discharging at this time). Adjust heat to 40°C, discharge at 191.3°C. (Belongs to light-medium roasting).

First Crack Stage: Maximum Air Damper

The first crack stage is one of the stages that requires the most caution and concentration during coffee roasting. Previously, due to continuous heating of coffee beans, moisture inside becomes water vapor.

Due to continued heating in later stages, water vapor and carbon dioxide from Maillard reaction create great pressure on the bean's cell structure. Finally, when pressure becomes too great and beans cannot withstand it, the coffee bean cell structure ruptures, and water vapor, carbon dioxide, and other substances gush out from inside—first crack begins. Therefore, first crack produces large amounts of smoke, so the maximum air damper is opened!

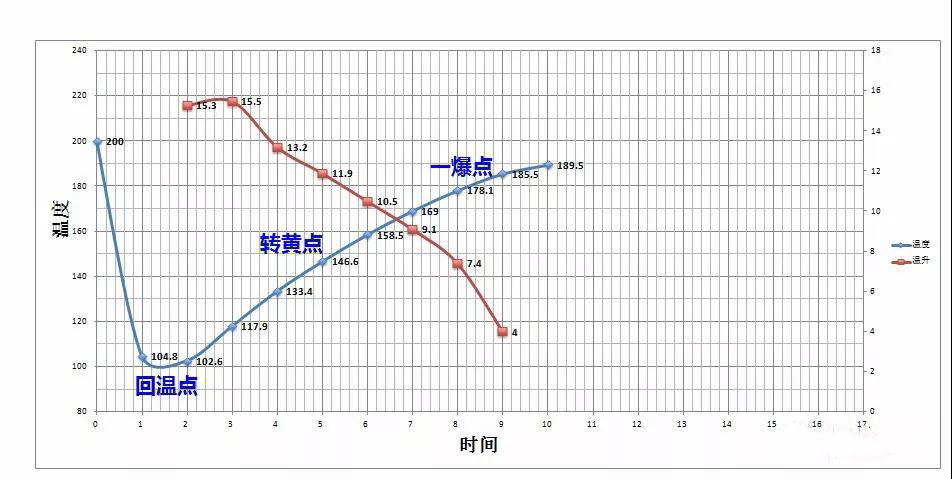

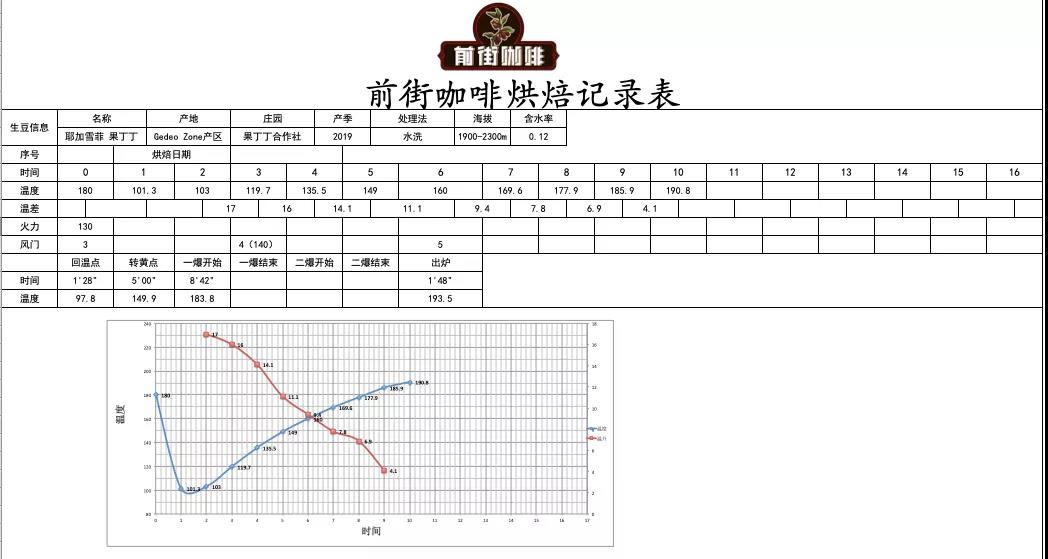

How FrontStreet Coffee Records Roasting Curves

Below is an example of roasting curves for washed Yirgacheffe Gudding:

FrontStreet Coffee's roasting process:

Roasting machine: Yangjia 600g semi-direct fire

Bean quantity: 300g

Return temperature point: 1 minute 28 seconds, 97.8°C

Yellowing point: 5 minutes, 149.1°C

First crack: 8 minutes 42 seconds, 138.8°C

Discharge: 1 minute 48 seconds, 193.5°C

Dense first crack discharge

Roast degree: Light roast

FrontStreet Coffee's cupping flavor 12 hours after roasting: Citrus and black tea on entry, with cream, caramel, and almond aftertaste as temperature changes, with obvious sweet aftertaste and clean, sweet mouthfeel.

What is the Best Time for Roasting Coffee Beans?

The best time point doesn't mean that discharging beans at a specific exact minute and second proves your roast degree or quality is consistent. This also involves the characteristics of the raw coffee beans themselves, the temperature rise rate during the entire roasting process, and other factors.

So for this question, without considering other factors, only discussing how to judge the roasting factor of discharge time, you can operate like this (this is a simplified version, assuming you already understand raw bean characteristics, normal return temperature point, fixed heat and other factors):

Step One: Make Assumptions

Based on your usual roasting experience, make a rough roasting prediction. For example, generally speaking, approximately:

- What time does first crack begin?

- How long will first crack last?

- How much time is there between first and second crack?

Step Two: Sampling

Take 11g samples at 30s, 50s, 60s after first crack begins; at 25%/50%/75% between first and second crack; before second crack begins; when second crack begins; and entering second crack.

Step Three: Cupping

Cup the sampled samples to determine which range best meets your expectations, then you can make your judgment!

However, for the same beans, different roasting rhythms greatly affect coffee taste, mouthfeel, and flavor tone. Generally, the coffee roasting process is divided into three stages: the dehydration stage before beans turn yellow; the browning reaction stage from when beans turn yellow and main chemical reactions (mainly Maillard reaction) begin until before first crack; and the development stage from after first crack to roasting end.

Adjusting roasting rhythm means adjusting the time and temperature rise of these three stages, as well as the return temperature point.

Generally:

Fast rhythm, overall short roasting time coffee will have lighter mouthfeel, lower complexity, bright acidity, and lively flavors. However, too fast roasting rhythm can easily make coffee have plant-like green flavors and underdeveloped flavors.

Slow rhythm, overall long roasting time coffee will have heavier mouthfeel, higher complexity, and more caramel chocolate tones. However, too slow roasting rhythm can cause dull flavors, mellow acidity, and low coffee cleanliness.

Generally, coffee roasting is divided into three stages, so how does adjusting the time of these three stages affect coffee taste?

Dehydration stage: Fast rhythm will create higher pressure inside coffee, lower mouthfeel, and higher cleanliness. Slow rhythm will create smaller accumulated pressure inside coffee, higher mouthfeel, and may make coffee flavors dull, with lower cleanliness and higher complexity. Because dehydration rhythm from slow to fast makes coffee's initial heat momentum and internal pressure go from small to large.

This directly affects the rhythm of the latter two roasting stages. Larger bean core pressure is unfavorable for Maillard reaction, producing fewer substances that bring body to coffee, replaced by preserving more floral and fruity aroma substances. The greater the initial accumulated heat momentum, the more it accelerates the rhythm of later processes.

Stage after yellowing: Maillard reaction begins. Shortening this stage's time and accelerating rhythm will reduce coffee flavor complexity, improve cleanliness, and make mouthfeel lighter. Conversely, slowing this stage's rhythm will increase coffee flavor complexity, have heavier mouthfeel, but cleanliness will decrease. The longer this stage, the more caramel tones coffee will have. Coffee flavors will also develop toward deep and single notes.

Development stage: From after first crack to roasting end. At this time, besides continued Maillard reaction, caramelization reaction also begins simultaneously. Fast rhythm development stage will give coffee lively, bright acidity, lower complexity, lower bitterness, and greatly varied aroma.

Slowing the development stage rhythm may make coffee flavors become monotonous and uninteresting, but will make acidity rounded and have good complexity. Too long can make rounded acidity become flat and uninteresting. Extending development time will also produce more chocolate and cream flavors.

Finally, FrontStreet Coffee wants to share "What qualifications should a good coffee roaster have?"

- Coffee Raw Bean Identification Ability: Basically, from identifying the appearance and characteristics of raw beans from major producing areas, understanding differences between new and old beans, to judging and screening defective beans, and even knowing how to find information about raw bean sources—these are all to ensure stable quality when purchasing raw beans.

- Coffee Roasting Technical Ability: Machine manufacturers should provide training including operation of roasting equipment, troubleshooting, and cleaning maintenance. Additionally, provide practical operations such as, at the same roast level, the differences caused by varying characteristics like moisture content and hardness of raw beans from major producing areas, the roasting curves and techniques needed, and controls for air damper, temperature, and heat during different roasting stages.

- Coffee Cupping and Bean Blending Ability: Basic cupping practice allows roasters to judge coffee quality and whether roasting completion is good or bad. It also strengthens ability to describe coffee flavors for customer sales explanations. Additionally, when blending house blends, they can grasp the characteristics each single-origin coffee should express, balance and coordinate various proportions, showcasing the unique taste of their own roasting coffee shop.

In summary, coffee roasting faces various difficulties. Only by being familiar with coffee roasting principles, continuously accumulating experience, and being adaptable can baristas master exquisite skills.

For more specialty coffee beans, please add FrontStreet Coffee on private WeChat, WeChat ID: kaixinguoguo0925

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

How to Judge Coffee Roast Levels: Comparison Chart of Espresso and American Coffee Bean Taste and Roasting Characteristics

For professional coffee knowledge exchange and more coffee bean information, please follow Coffee Workshop (WeChat public account: cafe_style). Complete guide to coffee roasting techniques | The purpose of coffee roasting and the characteristics of coffee beans mainly affect the taste and flavor of coffee. There are two major factors: 1. Green bean characteristics 2. Coffee bean roasting degree. The roasting of beans affects...

- Next

Practical Coffee Roasting Knowledge: Essential Baking Skills You Won't Learn in Coffee Roasting School

Professional coffee knowledge exchange. For more coffee bean information, please follow Coffee Workshop (WeChat public account cafe_style). Complete coffee roasting techniques | The purpose of coffee roasting and the characteristics of coffee beans. From the plantation to your cup, coffee's journey where aroma is most crucial is the roasting process. We grow coffee trees in tropical regions, concentrating the abundant sunshine from the equator into coffee beans, and then...

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee