What are the Flavor Differences Between Natural, Washed, Semi-Washed, and Honey Processed Coffee Beans?

For professional coffee knowledge exchange and more coffee bean information, please follow Coffee Workshop (WeChat official account: cafe_style)

The process of transforming coffee cherries into coffee beans is called coffee processing. While there are increasingly many coffee bean processing methods, FrontStreet Coffee's beans basically cover all current mainstream processing methods. The store also displays and exhibits beans with different processing methods for customers' reference. Today, let FrontStreet Coffee introduce the four most basic coffee bean processing methods: natural, washed, semi-washed, and honey processing.

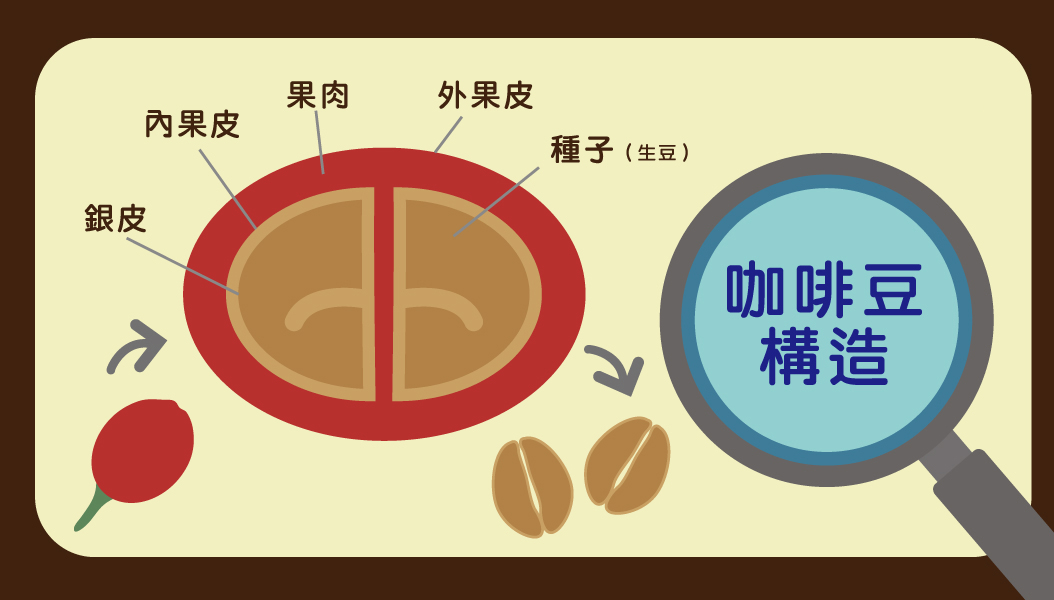

The Structure of Coffee Cherries

Cherry-like coffee fruits, from outside to inside, are respectively: skin, pulp, mucilage layer, parchment (seed coat), silver skin, and seed. The mucilage layer is about 1-2mm thick, which can be imagined as the translucent substance around tomato seeds, and is difficult to remove. The raw beans we generally buy are actually the innermost seeds, perhaps with some residual silver skin.

Various processing methods share the same goal: removing the skin to obtain the beans. Based on economic cost considerations and different natural environmental conditions such as climate, the bean extraction process may not be the same, but the process does affect the result!

Natural Processing Method

The natural processing method is the oldest and most hassle-free raw bean processing method.

Step 1: Removing Floating Beans

Pour the harvested coffee cherries into a large water tank. Mature, full cherries will sink to the bottom; underdeveloped or overripe cherries will float on the surface, and these floating beans must be removed.

Step 2: Natural Sun Drying

Next, place the entire coffee cherries with flesh, skin, and seeds onto the drying field for sun drying until the moisture content reaches about 12%. This takes about two to four weeks, depending on the producing region's climate.

Step 3: Hulling

Use a hulling machine to remove the dried hard skin, pulp, and parchment from the naturally dried fruit, and the raw beans will appear.

Advantages of Natural Processing

1. Simple and low processing cost.

2. Raw beans dry naturally within the pulp, absorbing the fruit's essence, resulting in rich fruit aroma, obvious sweetness, and excellent body.

Disadvantages of Natural Processing

1. Some producing regions don't remove floating beans during natural processing, causing inconsistent quality.

2. During the drying process, pulp can easily become moldy due to climate humidity, contaminating the raw beans.

3. Machine hulling inevitably damages raw beans, causing appearance defects.

FrontStreet Coffee selects Ethiopian natural Guji coffee beans for roasting and brewing.

FrontStreet Coffee Natural Guji GUJI NATURAL

Country: Ethiopia

Region: Guji

Altitude: 1800-2100m

Processing: Natural processing

Variety: Local native varieties

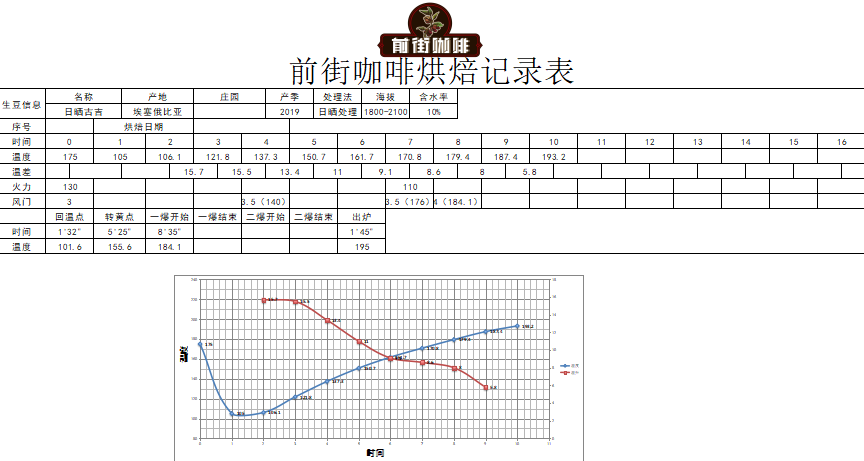

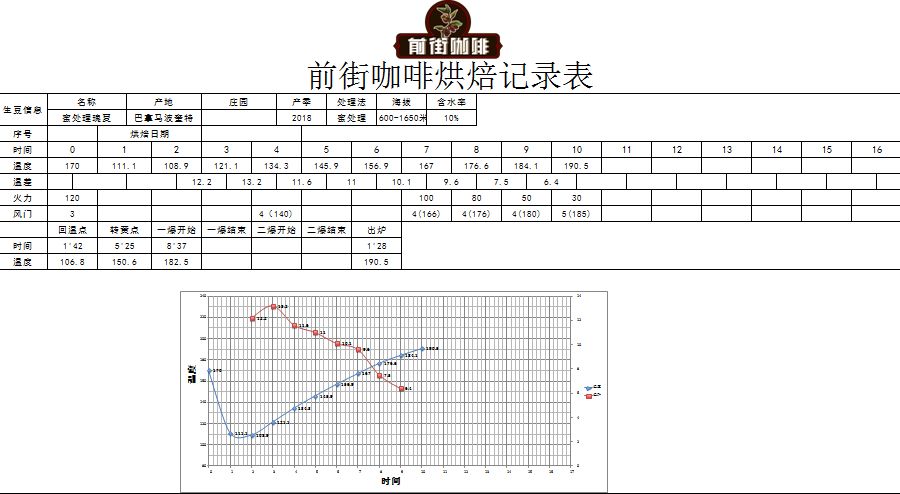

Roasting Recommendations

Preheat the roaster to 175°C, with heat at 130 and damper at 3. Return temperature at 1'32". When the roaster temperature reaches 140°C, open the damper to 3.5, keeping heat unchanged. When the roaster temperature reaches 155.6°C, the bean surface turns yellow, grassy smell completely disappears, entering the dehydration stage. When the roaster temperature reaches 176°C, adjust heat to 110, keeping damper unchanged.

At 7'28", ugly wrinkles and black spots appear on the bean surface, toast smell clearly turns to coffee aroma, which can be defined as the prelude to first crack. At this time, listen carefully for the sound of first crack. First crack begins at 8'35", adjust damper to 4, develop for 1'45" after first crack, and unload at 195°C.

Flavor: Tropical fruits, lychee, citrus, caramel, cream

Washed Processing Method

The washed processing method is currently the most common raw bean processing method.

Step 1: Removing Floating Beans (same as natural method)

Step 2: Removing Pulp

Send fresh cherries into a pulping machine to remove skin and pulp. Immature cherries, due to difficulty in pulp separation, will be screened out at this stage. After passing through the pulping machine, what remains is mucilage, parchment, and seeds.

Step 3: Fermentation to Remove Mucilage

Transfer the depulped seeds with mucilage into fermentation tanks. Although the name suggests "washing" method, it's not actually washing away the mucilage, but rather removing it through biological decomposition during fermentation. The fermentation process takes about 16-36 hours, during which frequent stirring is needed to accelerate mucilage separation from the seeds. Washed fermentation produces acidic substances such as citric acid, malic acid, and acetic acid. These acid values will penetrate the raw beans, making washed beans more acidic than natural beans. After fermentation is complete, it's time for actual washing—cleaning the beans again.

Step 4: Drying

After washing, the beans still need to be sun-dried or machine-dried until moisture content drops to 12%. Since washed beans have had pulp removed, during the drying process, there's no need to worry about mold issues like in natural processing. The dried parchment raw beans are not as hard as natural processing beans with pulp and skin, and can be hulled using a hulling machine to obtain raw beans.

Advantages of Washed Processing

1. Raw beans are dark green in color, complete in appearance, with good marketable quality.

2. Acidity and brightness are better than natural beans, and flavor is cleaner.

Disadvantages of Washed Processing

1. To obtain 200g of raw beans, 1kg of cherries need to be washed, consuming about 2-10 liters of clean water, making it costly.

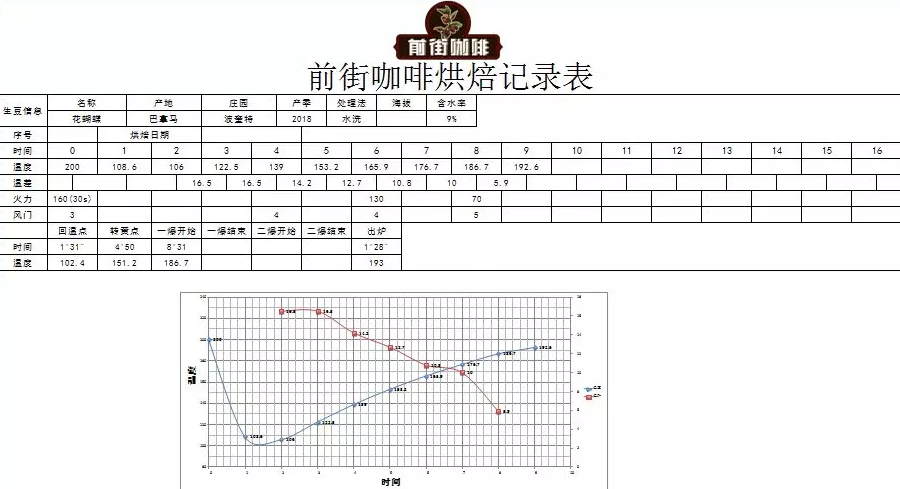

FrontStreet Coffee Panama Boquete Washed Mariposa

Region: Panama Boquete

Varieties: 70% Geisha, 30% Caturra & Catuai

Altitude: 1600-1650m

Processing: Washed processing

Roasting Profile

Yangjia 800N semi-direct flame roaster (roasting amount 550g)

Preheat roaster to 200°C, after 30 seconds adjust heat to 160, open damper to 3, return temperature at 1'31", maintain heat; turn yellow at 4'50", grassy smell disappears, entering dehydration stage, at 165°C reduce heat to 130°C, keep damper at 4.

At 7'50", dehydration complete, wrinkles and black spots appear on bean surface, toast smell turns to coffee aroma, prelude to first crack. At this time, pay attention to listen for first crack sound. First crack begins at 8'31", fully open damper to 5, adjust heat to 70°C. Development time after first crack is 1'28", unload at 193°C.

Flavor: Citrus, jasmine, honey, berries, overall flavor is clean, floral notes and citrus acidity are more prominent.

Semi-Washed Processing Method

An improved processing method that reduces water consumption compared to traditional washed processing.

Step 1: Removing Floating Beans (same as washed method)

Step 2: Removing Pulp (same as washed method)

Step 3: Mechanical Mucilage Removal

Traditional washed processing uses fermentation to remove mucilage, while the improved method uses a demucilager to mechanically remove mucilage.

Step 4: Drying

Sun-dry or machine-dry until moisture content reaches 12%. Semi-washed bean flavor falls between natural and washed beans—less acidic than washed beans, less sweet than natural beans.

Advantages of Semi-Washed Processing

It has the cleanliness of washed processing without requiring large amounts of water.

Disadvantages of Semi-Washed Processing

Although it's a hybrid of washed and natural processing, its process is as cumbersome as the washed method.

Colombia Isabella

Country: Colombia

Region: Huila

Variety: Pink Bourbon

Processing: Semi-washed

Altitude: 1760m

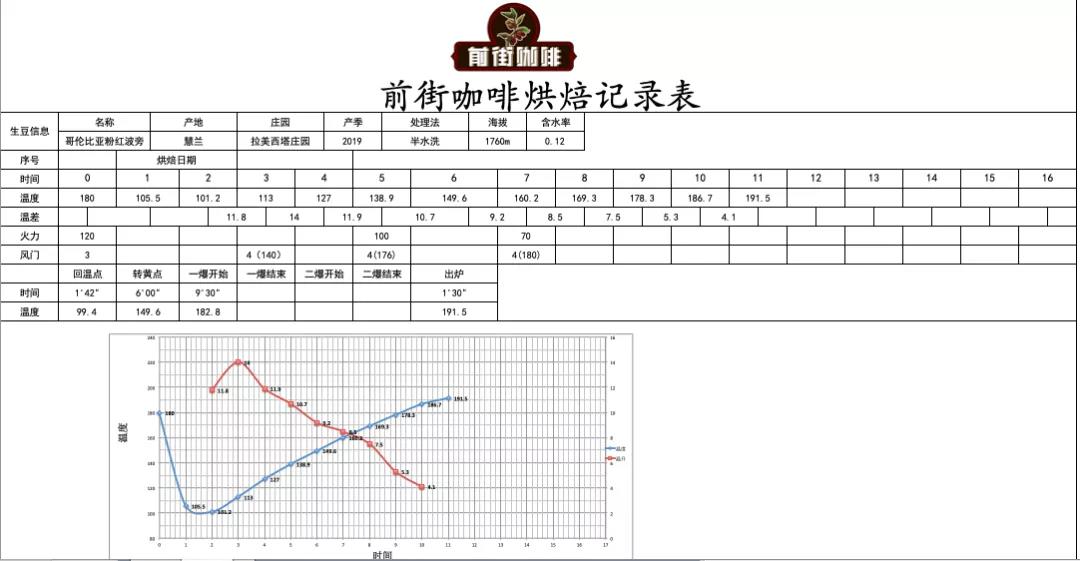

Roasting Profile

Preheat roaster to 180°C, open damper to 3, heat at 120; return temperature at 1'42", when roaster temperature reaches 140°C keep heat unchanged, open damper to 4; at this time bean surface turns yellow, grassy smell completely disappears, entering dehydration stage. At 176°C reduce heat to 100, at 180°C reduce heat to 70, keep damper unchanged.

At 8'17", ugly wrinkles and black spots appear on bean surface, toast smell clearly turns to coffee aroma, which can be defined as the prelude to first crack. At this time, listen carefully for the sound of first crack. First crack begins at 9'30", adjust damper to 5 (adjust heat very carefully, not so low as to eliminate cracking sound), develop for 1'30" after first crack, unload at 191.5°C.

Flavor: Entry has citrus, berries, cherry tomatoes. With temperature changes, there's honey sweetness, floral aftertaste, smooth and clean mouthfeel.

Honey Processing Method

What is honey processing? In its original English meaning, its scientific name should be "pulp natural." Similar to traditional wet processing, it removes the thick skin of coffee cherries while retaining the underlying sticky mucilage layer. Instead of using fermentation to remove the sticky mucilage layer, it allows this layer to dry directly, then removes the sticky layer and parchment.

FrontStreet Coffee tested three roasting profiles with Panama Boquete honey-processed Geisha coffee to compare their flavors and mouthfeel.

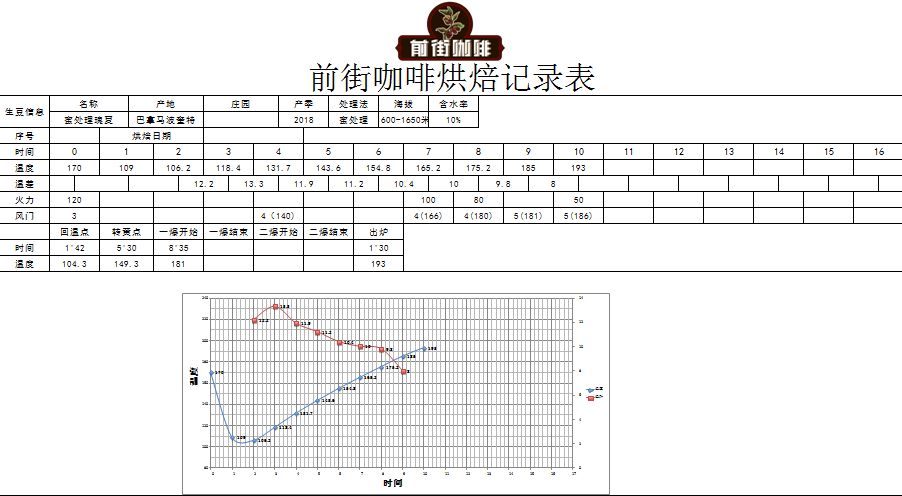

Profile One

Entry temperature 170°C, yellowing point at 5'30", first crack begins at 8'35", temperature 181°C, develop for 1'30" after first crack, unload at 193°C.

Agtron bean color value 78.2 (left image), Agtron ground color value 86.4 (right image), Roast Delta value is 8.2.

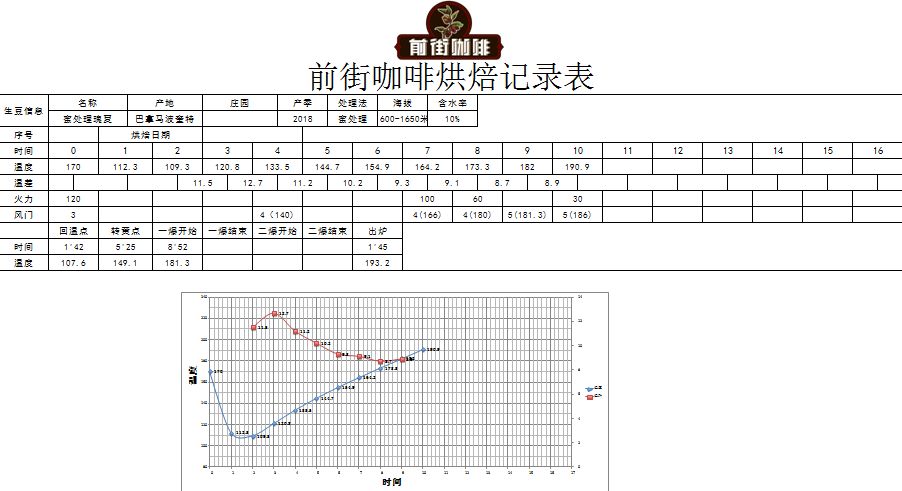

Profile Two

Entry temperature 170°C, yellowing point at 5'25", first crack begins at 8'52", temperature 181.3°C, develop for 1'45" after first crack, unload at 193.2°C.

Agtron bean color value 76.5 (left image), Agtron ground color value 86 (right image), Roast Delta value is 9.5.

Profile Three

Entry temperature 170°C, yellowing point at 5'25", first crack begins at 8'37", temperature 182.5°C, develop for 1'28" after first crack, unload at 190.5°C.

Agtron bean color value 82.6 (left image), Agtron ground color value 90.3 (right image), Roast Delta value is 7.7.

Cupping Comparison

[Profile One] When slurping: plum, lime, citrus, cream flavors, with green tea texture and fermentation aroma.

[Profile Two] When slurping: sweet orange, plum, citrus, tropical fruit acidity, cream with light fermentation aroma and floral notes.

[Profile Three] When slurping: lemon, plum, sweet orange, cream flavors, with jasmine floral notes and fermentation aroma, ending with oolong tea texture.

After cupping, we felt that [Profile One]'s flavor wasn't concentrated enough and had relatively thin flavor layers. Both [Profile Two] and [Profile Three] performed excellently in sweet and sour aspects. We decided to brew one pot each of [Profile Two] and [Profile Three] using pour-over method to see how these two profiles perform under pour-over brewing.

Parameters: Water temperature: 90°C; Medium-fine grind: VARIO 5O (Chinese standard 20-mesh sieve passing rate 80%); Dripper: Hario V60; Coffee-to-water ratio: 1:15.

Method: Poured in stages. Bloom with 30g water for 30 seconds, pour to 125g and stop, wait for water level to drop just before exposing the coffee bed, then continue pouring to 225g and stop. When water level drops just before exposing the coffee bed, remove the dripper (timing starts from bloom). Extraction time is two minutes.

[Profile Two] Entry has lime, plum, pineapple acidity, with nut flavors emerging in the middle, ending with cocoa and nut flavors, caramel aftertaste and ginger flower finish.

[Profile Three] Aroma has fermentation and floral notes, entry has citrus, lemon acidity, with creamy sweetness emerging in the middle, ending with green tea texture, sucrose and honey aftertaste.

Difficulties of Honey Processing

1. During the drying process, since the sticky mucilage layer is still on the coffee beans, high-frequency turning is necessary in the first few days to prevent coffee beans from clumping together. Therefore, it requires more manual labor than general washed processing.

2. If drying cannot be completed quickly, over-fermentation easily occurs.

3. If turning is insufficient, or the overall environment is too humid and cold, or the sticky mucilage layer is left too thick, coffee beans can easily become moldy. Therefore, some coffee estates use machines to control the thickness of the retained sticky mucilage layer, allowing coffee beans to dry faster and achieving better overall consistency in mouthfeel.

4. Compared to wet processing, it requires more space and takes longer days to dry.

Enhancement Methods

1. During the first 2-3 days of sun drying, it's best to complete under all-day monitoring. During this time, part of the mucilage layer has already dried, and the coffee is less likely to develop undesirable fermentation flavors.

2. During the drying process, elevated drying racks can be used to improve ventilation throughout the process, making it less prone to mold.

3. If drying on a courtyard or terrace, the mucilage layer's slime will seep into the courtyard, so it must be thoroughly cleaned before drying the next batch of coffee beans.

Flavor Characteristics

The advantage of honey processing is enhancing coffee's body and sweetness (hence also called honey process or miel process in English), while relatively reducing its acidity, and the aroma becomes more delicate. However, this is the flavor when honey processing is perfectly executed. When poorly executed, it tastes with undesirable vinegar acidity, like onion or garlic spicy aromas. Even when executed quite well, it still carries some earthy notes, the aftertaste is less clean, and off-flavors are heavier than general washed processing. Therefore, overall, adopting honey processing involves much higher risk than general wet processing.

For more specialty coffee beans, please add FrontStreet Coffee on WeChat: kaixinguoguo0925

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Specialty Coffee Brewing Tutorial: How to Brew a Perfect Cup with Coffee Beans

Professional coffee knowledge exchange and more coffee bean information. Follow Coffee Workshop (WeChat official account: cafe_style) to understand how to use coffee beans and how to brew a perfect cup of coffee, just as an artist knows how to use their paintbrush, or a scientist understands how to apply scientific equations. Once you have mastered the above professional knowledge, you can start with simple Espresso

- Next

My First Green Bean Purchase Experience! Details to Pay Attention to When Buying Coffee Beans

Professional coffee knowledge exchange For more coffee bean information Please follow Coffee Workshop (WeChat public account cafe_style) When buying coffee beans Pay attention to defect rate! Defect rate! Defect rate! 1 Mandheling G1, 500g green beans, 140 defective beans, defect rate 29%, this high defect rate batch, the appearance looks quite good, upon careful selection, surprisingly so many defective beans, the more you pick, the more you find

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee