What Flavors Does Washed Coffee Processing Produce & What Are Its Disadvantages

Professional coffee knowledge exchange. For more coffee bean information, please follow Coffee Workshop (WeChat official account: cafe_style).

Washed Method

Due to the numerous disadvantages of the natural method, the washed method was invented. The washed method is currently the most widely used processing method. The biggest difference from the natural method is the use of fermentation to remove the mucilage layer.

Step 1: Remove Floating Beans (Same as Natural Method)

Step 2: Depulp

Fresh cherries are sent into a pulping machine to remove the skin and pulp. After passing through the pulping machine, what remains are mucilage, parchment, silver skin, and seeds. Meanwhile, immature cherries, which are difficult to separate from the pulp, are screened out at this stage.

Step 3: Ferment to Remove Mucilage

The purpose of this step is to use biological processing methods to remove the mucilage. The depulped seeds with mucilage are transferred to fermentation tanks. Although the method is called "washed," it doesn't actually wash away the mucilage but rather removes it through biological decomposition during fermentation. The fermentation process takes about 16-36 hours, during which the mixture must be stirred frequently to accelerate the separation of mucilage from the seeds.

Step 4: Washing

After completing fermentation and removing mucilage, fermentation bacteria and impurities remain on the coffee beans, so the beans are washed again. To achieve thorough cleaning, this step consumes a large amount of fresh water.

Step 5: Drying and Removing Parchment and Silver Skin

After washing, the beans need to be sun-dried or machine-dried to reduce moisture content to 12%. Since the pulp has been removed in the washed method, there's no need to worry about mold issues during drying as with the natural method. The dried parchment beans are not as hard as natural-processed beans containing pulp and skin, and can be hulled using a hulling machine to obtain green beans.

Advantages

Since the pulp is removed from the beginning, there's no need to worry about mold problems as with the natural method.

The appearance is more complete and aesthetically pleasing.

Disadvantages

The process is complex and tedious, making it much more expensive than the natural method.

It requires large amounts of fresh water. To obtain 1 kilogram of coffee beans, 40-50 liters of fresh water are needed, so it's less commonly used in water-scarce regions.

Flavor Profile

Fermentation in the washed method produces acidic substances such as citric acid, malic acid, and acetic acid. These acid values penetrate the green beans, making washed-method beans more acidic than natural-processed beans. The acidity and brightness are better than natural beans, and the flavor is cleaner.

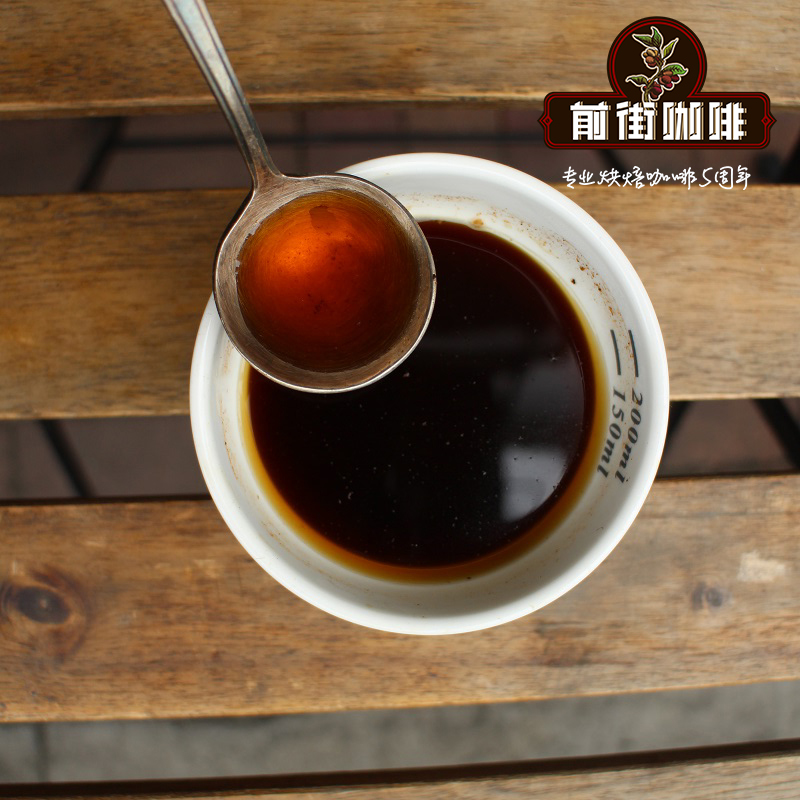

Taking FrontStreet Coffee's Kenya Asali as an example, the K72 refined washed process brings bright fruit acidity to this coffee, along with rich berry aromas.

FrontStreet Coffee's Recommended Brewing Parameters:

V60/90°C/1:15/Time 2'10"

Flavor: Rich cherry tomato flavor, with brown sugar and cane sugar sweetness.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Coffee Bean Processing Methods: Understanding Natural Processing and Its Characteristics

Explore professional coffee knowledge and learn about natural coffee bean processing methods. Follow Coffee Workshop (WeChat official account: cafe_style) for comprehensive coffee bean information. Natural processing represents the most traditional method of coffee bean treatment, where freshly harvested coffee cherries are carefully spread evenly on drying grounds, allowing sunlight to naturally remove moisture from the fruit's skin and pulp.

- Next

Pros and Cons of Washed Processing Method Characteristics of Coffee Washed Processing Coffee Bean Washed Processing

Professional coffee knowledge exchange for more coffee bean information please follow Coffee Workshop WeChat Official Account cafe_style Generally what we call the washed method refers to the full washed method First remove the outer skin and pulp leaving the mucilage layer then put the coffee beans into fermentation tanks to dissolve the mucilage layer before drying and finally remove the outer skin The advantage is high quality green bean rate while the disadvantage is

Related

- How to make bubble ice American so that it will not spill over? Share 5 tips for making bubbly coffee! How to make cold extract sparkling coffee? Do I have to add espresso to bubbly coffee?

- Can a mocha pot make lattes? How to mix the ratio of milk and coffee in a mocha pot? How to make Australian white coffee in a mocha pot? How to make mocha pot milk coffee the strongest?

- How long is the best time to brew hand-brewed coffee? What should I do after 2 minutes of making coffee by hand and not filtering it? How long is it normal to brew coffee by hand?

- 30 years ago, public toilets were renovated into coffee shops?! Multiple responses: The store will not open

- Well-known tea brands have been exposed to the closure of many stores?!

- Cold Brew, Iced Drip, Iced Americano, Iced Japanese Coffee: Do You Really Understand the Difference?

- Differences Between Cold Drip and Cold Brew Coffee: Cold Drip vs Americano, and Iced Coffee Varieties Introduction

- Cold Brew Coffee Preparation Methods, Extraction Ratios, Flavor Characteristics, and Coffee Bean Recommendations

- The Unique Characteristics of Cold Brew Coffee Flavor Is Cold Brew Better Than Hot Coffee What Are the Differences

- The Difference Between Cold Drip and Cold Brew Coffee Is Cold Drip True Black Coffee